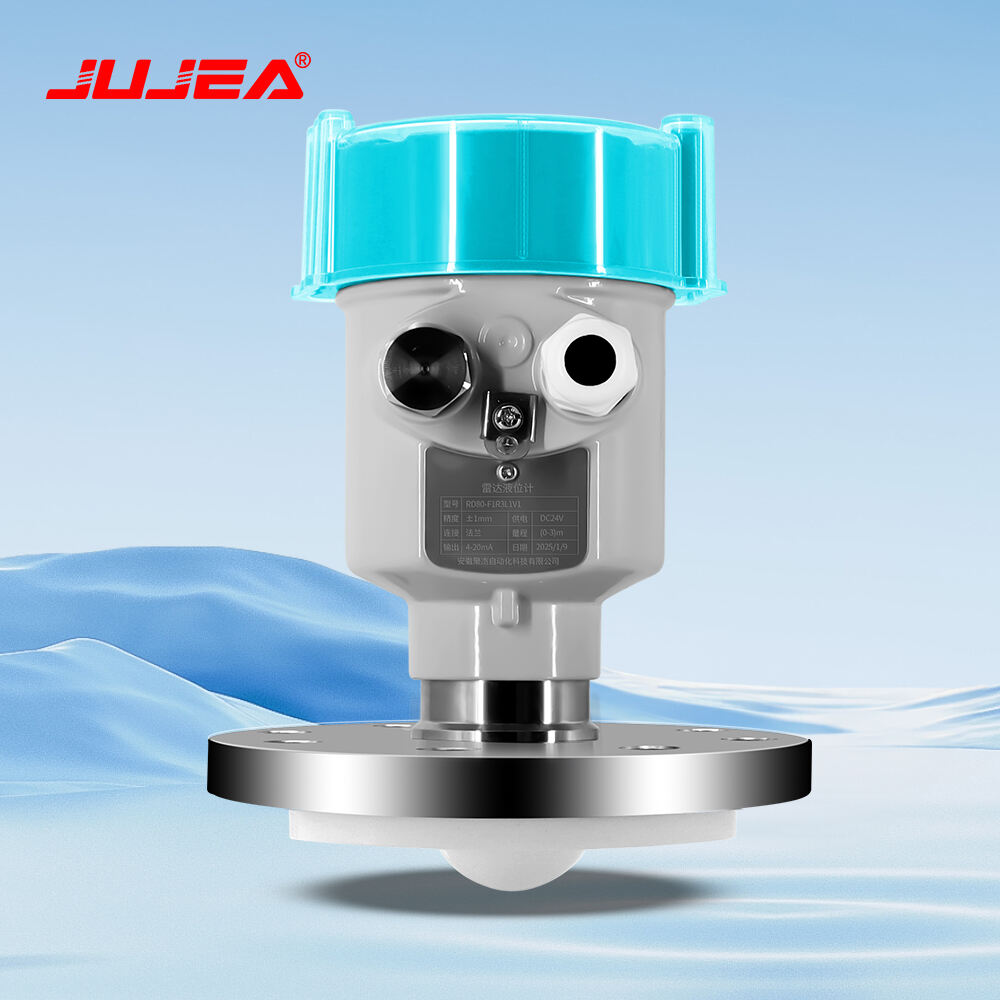

flow meter transmitter

A flow meter transmitter is a sophisticated measurement instrument that plays a crucial role in modern industrial processes by accurately monitoring and transmitting fluid flow data. This essential device combines precise measurement capabilities with advanced signal processing to provide real-time flow rate information across various applications. The transmitter works by converting physical flow measurements into standardized electronic signals, typically 4-20mA or digital protocols, making it compatible with most control systems. It features multiple configuration options to accommodate different fluid types, flow ranges, and operating conditions. The technology incorporates advanced diagnostics and self-monitoring capabilities, ensuring reliable performance and early detection of potential issues. These devices are designed to maintain accuracy across varying process conditions, including temperature and pressure fluctuations. Modern flow meter transmitters often include digital displays for local reading, multiple output options for system integration, and built-in calculation functions for parameters like total flow and flow rate averaging. They are engineered to operate in harsh industrial environments, with robust construction and protective features against electromagnetic interference, vibration, and extreme temperatures. The versatility of flow meter transmitters makes them indispensable in industries such as oil and gas, water treatment, chemical processing, and pharmaceutical manufacturing.