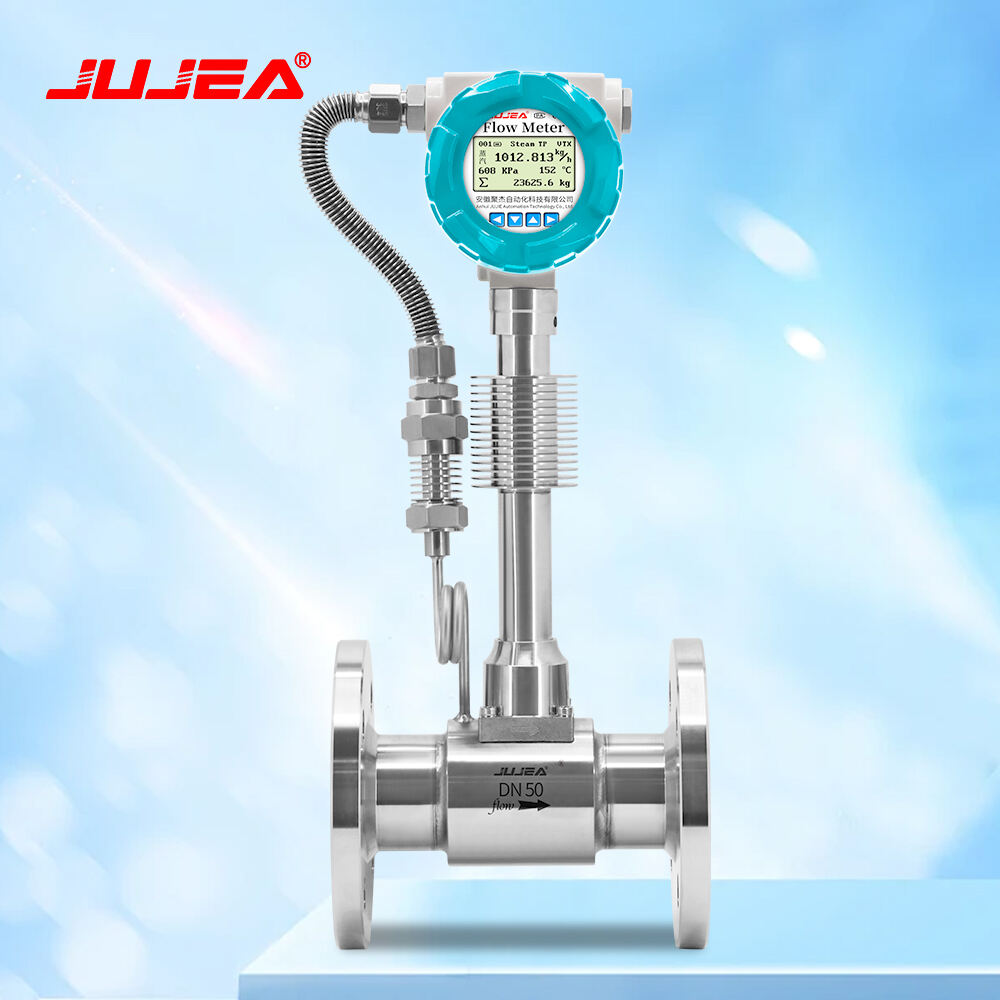

प्रवाह मापन

प्रवाह मापन औद्योगिक संचालन में एक महत्वपूर्ण प्रक्रिया है, जिसमें पाइप, चैनल और सिस्टम के माध्यम से तरल पदार्थों की गति की मात्रा और निगरानी शामिल है। यह उन्नत तकनीक चुंबकीय, पराध्वनिक और अंतराल दबाव सेंसर सहित विभिन्न तरीकों का उपयोग करके तरल पदार्थों और गैसों की प्रवाह दर, वेग और आयतन को सटीक रूप से निर्धारित करती है। आधुनिक प्रवाह मापन प्रणालियों में उन्नत डिजिटल तकनीकों का एकीकरण होता है, जो वास्तविक समय में निगरानी की सुविधा और सटीक डेटा संग्रह प्रदान करती हैं। ये प्रणालियाँ जल उपचार, रासायनिक प्रसंस्करण से लेकर तेल और गैस उत्पादन जैसे विभिन्न उद्योगों में आवश्यक हैं, जिससे सटीक सामग्री हैंडलिंग और प्रक्रिया नियंत्रण सुनिश्चित होता है। इस तकनीक में स्मार्ट सेंसर और डिजिटल इंटरफ़ेस शामिल हैं, जो मौजूदा नियंत्रण प्रणालियों के साथ बेमलूम एकीकरण की अनुमति देते हैं, जो निरंतर निगरानी और समायोजन की क्षमता प्रदान करता है। प्रवाह मापन उपकरणों को विभिन्न स्थितियों, तापमानों और दबाव स्तरों में सटीकता बनाए रखने के लिए डिज़ाइन किया गया है, जिससे वे गुणवत्ता नियंत्रण और नियामक अनुपालन के लिए अमूल्य हैं। इन प्रणालियों में उन्नत कैलिब्रेशन की क्षमता भी है, जो विस्तारित अवधि के लिए स्थायी सटीकता सुनिश्चित करती है, जबकि रखरखाव आवश्यकताओं को कम करती है।