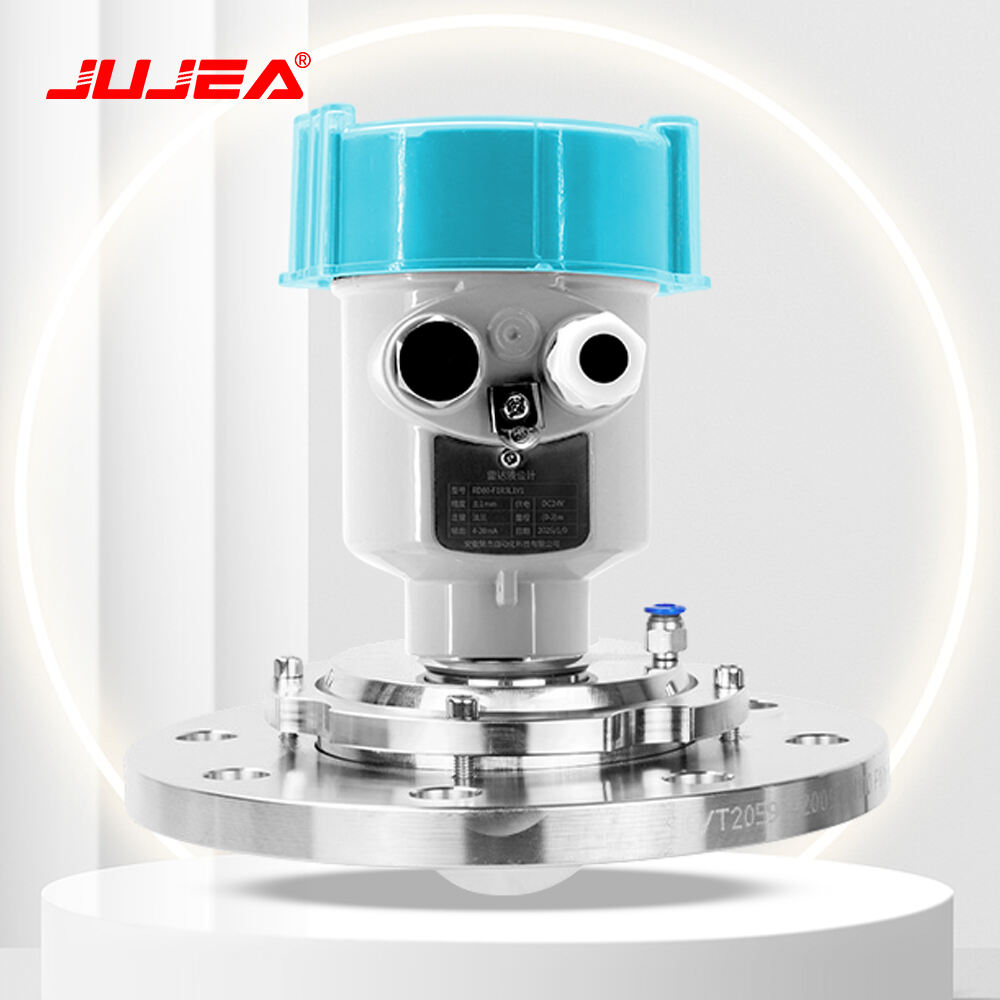

szintérzékelő

A szintérzékelő egy korszerű mérőberendezés, amely folyadékok, porok és szemcsés anyagok tartályban vagy edényben lévő szintjének meghatározására szolgál. Ezek az érzékelők különféle technológiákat alkalmaznak, mint például ultrahangos, kapacitív, optikai és mágneses elveket, hogy pontos és megbízható méréseket biztosítsanak. A szintérzékelő elsődleges funkciója az, hogy folyamatosan figyelje és jelentse a tartály tartalmának szintjét, lehetővé téve az hatékony készletkezelést és folyamatirányítást. A modern szintérzékelők kiegészítő funkciókkal rendelkeznek, mint például digitális kijelző, távoli felügyeleti képesség és integráció az ipari automatizálási rendszerekbe. Ezek a szenzorok különféle környezetekben képesek üzemelni, szabványos ipari körülményektől kezdve egészen extrém feltételekig, magas hőmérséklet, nyomás vagy korrozív anyagok jelenlétében. A technológia mind pontszerű szintdetektálást kínál egyszerű tele/üres riasztásokhoz, mind folyamatos szintfelügyeletet részletes mérésekhez. Ezek az érzékelők kiemelt szerepet játszanak több iparágban is, beleértve a vegyipart, az élelmiszer- és italgyártást, a vízkezelő üzemeket és az olaj- és gázipari műveleteket. Biztosítják az erőforrások optimális felhasználását, megakadályozzák a túlfolyási eseményeket és fenntartják a termelési hatékonyságot a pontos szintvezérlés és -figyelés révén.