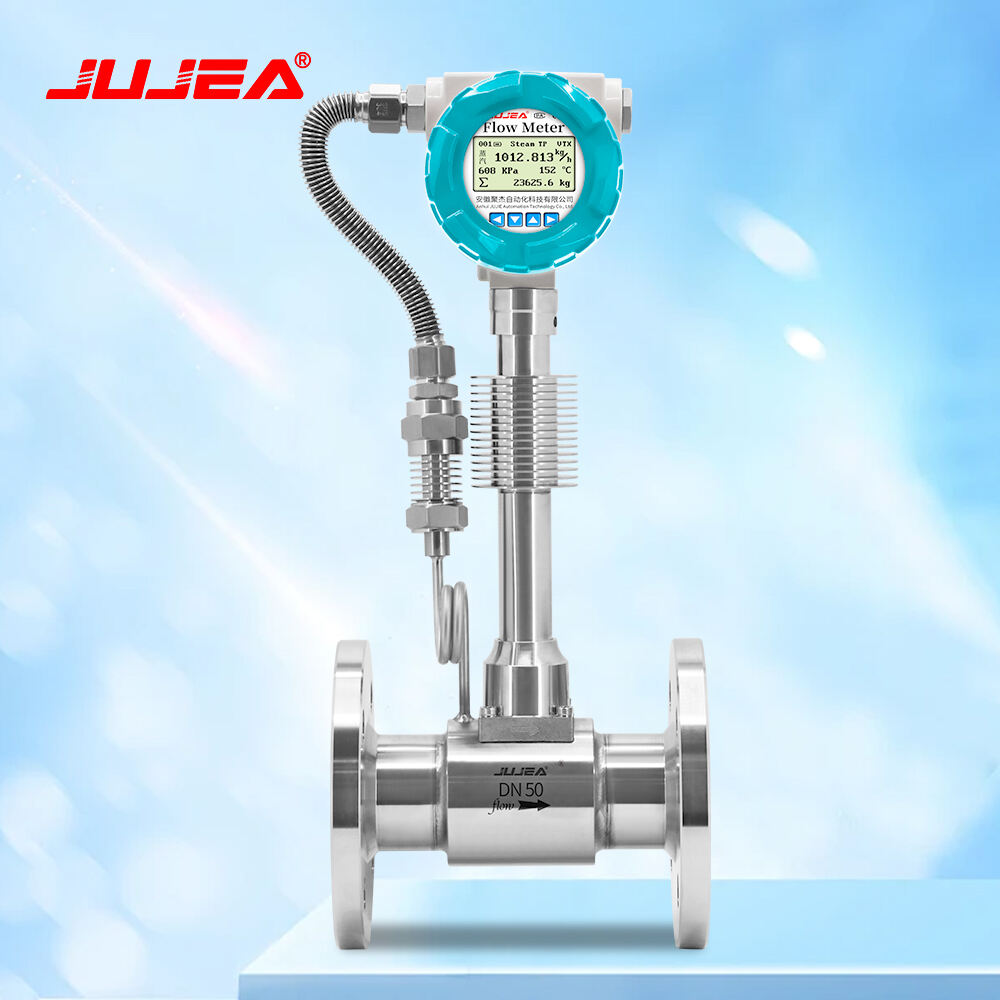

transmisi aliran turbin

Sebuah transmitter aliran turbin adalah perangkat pengukur canggih yang dirancang untuk secara akurat memantau dan mengukur laju aliran fluida dalam berbagai aplikasi industri. Instrumen presisi ini bekerja berdasarkan prinsip mengubah energi mekanik dari fluida yang mengalir menjadi sinyal listrik. Perangkat ini terdiri dari rotor berbilah ganda yang berputar ketika fluida mengalir melaluinya, dengan kecepatan putaran yang berbanding lurus dengan laju aliran. Transmitter kemudian mengubah pergerakan mekanis ini menjadi sinyal elektronik yang dapat dengan mudah diinterpretasikan dan dipantau. Transmitter aliran turbin modern dilengkapi dengan fitur canggih seperti pemrosesan sinyal digital, kompensasi suhu, dan kemampuan transmisi data waktu nyata. Perangkat-perangkat ini unggul dalam aplikasi yang membutuhkan tingkat akurasi tinggi, terutama di industri minyak dan gas, pengolahan kimia, serta pengolahan air. Konstruksi transmitter yang kuat umumnya mencakup komponen-komponen baja tahan karat, sehingga menjamin daya tahan dalam lingkungan industri yang keras. Dengan tingkat akurasi pengukuran yang biasanya mencapai ±0,5% dari pembacaan, instrumen-instrumen ini memberikan pengukuran aliran yang andal pada berbagai kisaran laju aliran. Kemampuan integrasi transmitter aliran turbin modern memungkinkan mereka terhubung secara mulus dengan berbagai sistem kontrol, menjadikannya komponen penting dalam sistem kontrol proses otomatis.