הנחיות חשובות להתקנת מד זרימה מוצלחת

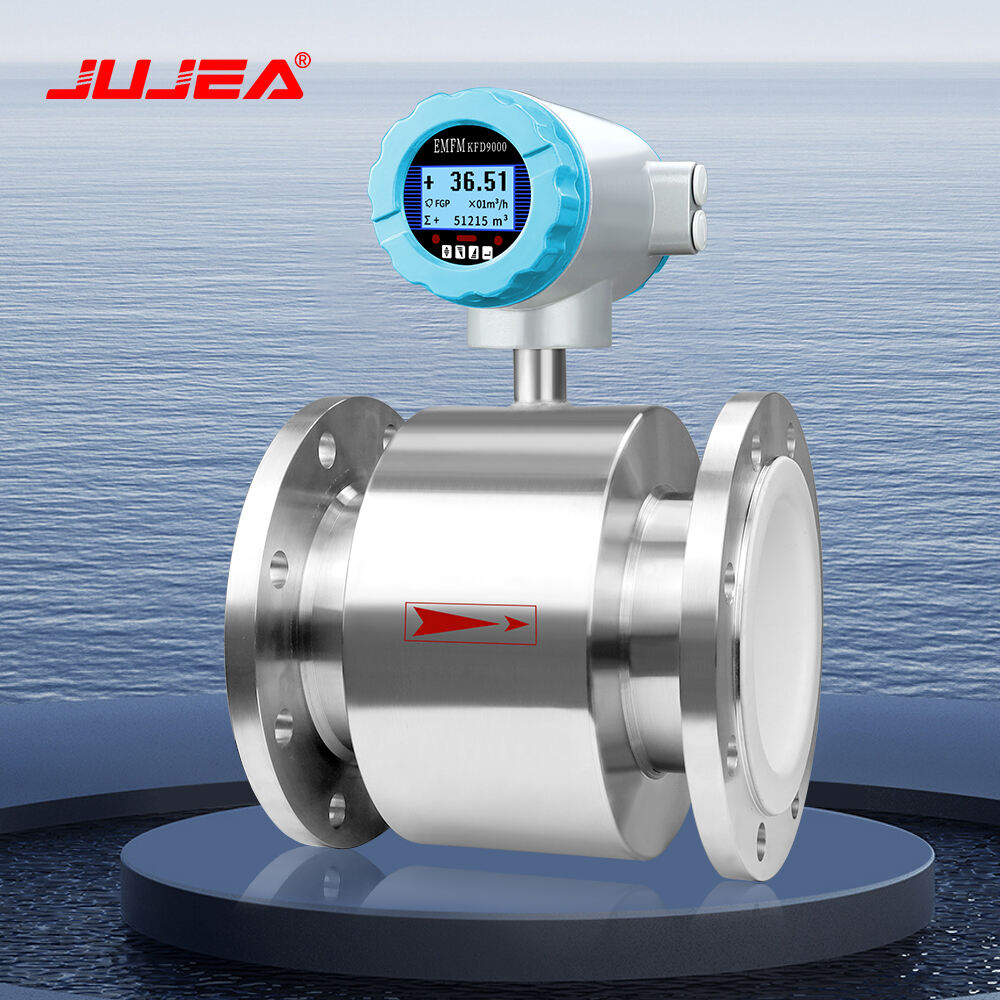

התקנת מזין זרימה התקנה נכונה היא קריטית להשגת מדידות מדויקות וביצועים אופטימליים. בין אם השקעתם במד זרימה מגנטי, אולטראסוני או קוריוליס, ההתקנה הנכונה יכולה להפוך את הפער בין נתונים מהימנים לשגיאות מדידה יקרות. מדריך מקיף זה יוביל אתכם דרך השלבים והשקולים החשובים כדי להבטיח שהתקנת מד הזרימה שלכם ת cumpl עם התקנים התעשייתיים ותספק תוצאות אמינות. עבור חברות שמקבלות ציוד, שותפות עם יצרן מכשירי ומדדי זרימה מה trusted בסין או ספק לבקרת זרימה ומדידה בסין יכולה להבטיח מספקים איכותיים ותמיכה מקצועית.

תכנון והכנה לפני ההתקנה

הערכת אתר והתחשבויות סביבתיות

לפני תחילת תהליך ההתקנה של מד זרימה, יש צורך בהערכת אתר מפורטת. יש לקחת בחשבון גורמים כגון טמפרטורת הסביבה, רמות הלחות ומקורות הפרעות אלקטרומגנטיות פוטנציאליים. מיקום ההתקנה צריך לספק הגנה מספקת מתנאי מזג אוויר קיצוניים ולשמור על סביבה יציבה לצורך דיוק עקבי במדידה. בנוסף, יש לוודא שקיים מספיק מקום לגישה לצורך תחזוקה וاجرואים של כיול.

קחו זמן כדי לרשום את תצורת הצינורות הקיימת ולזהות כל מכשולים פוטנציאליים שעלולים להשפיע על ביצועי מד הזרימה. זה כולל ציון נוכחות של שסתומים, חיבורים או אלמנטים אחרים המפריעים לזרימה שעלולים להשפיע על דיוק המדידה. תכנון נכון בשלב זה יכול למנוע שינויים יקרים בהמשך.

כלים נדרשים ואמצעי בטיחות

איסוף הכלים וציוד הבטיחות הדרושים הוא שלב הכנה חשוב. כלים סטנדרטיים להתקנה כוללים משוכות צינורות, מאוזנים, מכשירי מדידה וחיבורים מתאימים. בהתאם לסוג מונה השטף שלך, ייתכן שתצטרכו ציוד מיוחד כגון כלים ייעודיים לישור פלנצות או מכשירי בדיקה חשמלית מסוימים.

אי-אפשר להתפשר על הבטיחות במהלך התקנת מונה שטף. ודאו שאתם מצויידים בציוד הגנה אישי (PPE) מתאים, הכולל משקפי 보טיחות, כפפות ומגפיים עם קצה מחוזק. להתקנות הכוללות חומרים מסוכנים או מקומות חסומים, ייתכן שיידרשו אמצעי בטיחות נוספים ורשיונות.

שקולות מיקום והתקנה מתאימות

דרישות של ריצה ישרה

אחת היבטים החשובים ביותר בהתקנת מדדי זרימה היא שמירה על מרחקי ריצה ישרים מספקים. מקטעי צינור ישרים לפני ואחרי מדד הזרימה עוזרים להקים פרופילי זרימה מפותחים באופן מלא, שחשובים למדידות מדויקות. סוגי מדדי זרימה שונים דורשים אורכי ריצה ישרה שונים, בדרך כלל בין 5 ל-20 קטרי צינור לפני המדידה ו-2 עד 5 קטרי צינור לאחריה.

אם מגבלות של שטח גובות שהשגת אורכי הריצה הישרים המומלצים אינה אפשרית, יש לבדוק את אפשרות התקנת מאנות זרימה או לוחות התנעה. מכשירים אלו יכולים לעזור לנרמל דפוסי זרימה במרחקים קצרים יותר, אם כי יש להשתמש בהם בזהירות מכיוון שהם עלולים לגרום לנפילות לחץ נוספות.

כיוון ומבנה תמיכה

הכיוון של מד הזרימה משפיע בצורה משמעותית על ביצועיו. מרבית המדidores אמורים להותקן בקטעי צינור אופקיים, אם כי חלק מהעיצובים יכולים לעמוד בהתקנה אנכית. יש לוודא שהמד מיושר לכיוון הזרימה כפי שמסומן על ידי סימן החץ של היצרן. כל סטייה מהכיוון המומלץ עשויה להוביל לאי דיוקים במדידה.

מבנים תמיכה מתאימים הם חיוניים ngănת לחץ על גוף המד ועל הצינורות המחוברים. יש להתקין תמיכות צינור מתאימות גם לפני וגם אחרי המד, כדי לשמור על יציבות ולמנוע רעדים. מערכת ההתקנה צריכה לקחת בחשבון התפשטות תרמית ותנועה פוטנציאלית במערכת הצינורות.

חיבורים חשמליים וסיגנלים

דרישות חשמל

התקנת חשמל מתאימה היא קריטית לפעולת מד זרימה. ודאו שמקור החשמל עומד בדרישות של היצרן מבחינת מתח, תדירות וזרם. התקינו התקני הגנה על המעגל המתאימים ושקלו להשתמש במקור חילוץ חשמל (UPS) לApplications קריטיות.

לולאות ארקון יכולות להשפיע משמעותית על דיוק המדידה. יישמו טכניקותproper earthing בהתאם להנחיות היצרן ולתקנות החשמל המקומיות. באזורים עם הפרעות אלקטרומגנטיות גבוהות, שקלו להשתמש בכבלים משוריינים ואמצעי earthing נוספים.

תצורת פלט אות

מדדי זרימה מודרניים מציעים לעיתים קרובות מספר אפשרויות פלט, כולל פלט אנלוגי, דיגיטלי ותקשורת רשת. בחרו את סוג הפלט המתאים לפי דרישות מערכת הבקרה שלכם ודאו מסלולי כבלים מתאימים כדי למנוע הפרעות. בעת שימוש באותות אנלוגיים, ודאו כי סקלול וכיול טווחי הפלט מתבצעים נכון.

לתקשורת דיגיטלית, הגדר את פרמטרי הרשת כגון כתובות ופרוטוקולים בהתאם לארכיטקטורת המערכת. יש לרשום את כל הגדרות התקשורת לצורך ייחוס עתידי ופתרון תקלות. בדיקות שגרתיות של שלמות האות עוזרות לשמור על העברה אמינה של נתונים.

נהלי הפעלה ואימות

בדיקות וכיול ראשוניים

לאחר השלמת ההתקנה של מד זרימה, יש לבצע בדיקה מקיפה כדי לאשר פעילות תקינה. התחלו בבדיקות פונקציונליות בסיסיות, והבדקו קיום של דליפות ופלט אות תקין. ודאו קריאות של זרימה אפסית ובצעו התאמות כיול ראשוניות לפי הצורך. יש לרשום את כל תוצאות הבדיקה ונתוני הכיול לצורך ייחוס עתידי.

שקלו לבצע אימות זרימה באמצעות תקן ייחוס ידוע או מדידת השוואה זמנית. זה עוזר לאשר את דיוק ההתקנה ויכол לזהות בעיות פוטנציאליות לפני הפעלת העמדה. חברות רבות מציעות שירותי הנפקה או יכולות להמליץ על טכנאים מוסמכים לשלב קריטי זה.

תיעוד והדרכה

החזיקו רשומות מפורטות של תהליך ההתקנה, כולל תמונות, תרשימים והגדרות תצורה. צרו או עדכנו את תיעוד המערכת כדיสะкер את ההתקנה החדשה, כולל אישורי כיול ולוחות זמנים לשמרון. תיעוד זה הוא בעל ערך רב לפתרון תקלות עתידיות ולציות לרגולציה.

הדרכו את המפעילים וצוות השמירה על תפעול נכון של העמדה ונהלי khắcעת בעיות בסיסיים. הבנת פרמטרי תפעול נורמליים וסימני אזהרה עוזרת להבטיח זיהוי מוקדם של בעיות פוטנציאליות. הדרכות עדכון שגרתי שומרות על הצוות מעודכן עם שיטות עבודה מומלצות ותכונות חדשות.

שאלות נפוצות

מהו התדירות בה עליי כייל את מד הזרימה לאחר ההתקנה?

תדירות הכיול תלויה במספר גורמים, ביניהם סוג מד הזרימה, תנאי התהליך ודרישות רגולטוריות. באופן כללי, מומלץ לבצע כיול שנתי, אם כי ביישומים קריטיים עלולה להיות דרישה לאימות תכוף יותר. יש תמיד לעקוב אחר ההנחיות של היצרן והתקנים התעשייתיים עבור היישום הספציפי שלך.

אילו סימנים מצביעים על כך שההתקנה של מד הזרימה שלי עשויה להזדקק להתאמה?

מציינים נפוצים כוללים קריאות לא יציבות, סטייה בלתי צפויה במדידה, רעש או רטט מוגזם, ו meldungen שגיאה מאבחוני המETER. מעקב שוטף אחרי הפרמטרים האלה עוזר לזהות בעיות פוטנציאליות לפני שהן משפיעות בצורה משמעותית על פעולות התהליך.

האם ניתן להתקין מד זרימה בקטע צינור אנכי?

בעוד שזרם של מונים רבים ניתן להתקנה בצינורות אנכיים, קיימים דרישות ומגבלות מסוימות. מועדף לרוב זרימה כלפי מעלה כדי להבטיח תנאים של צינור מלא. יש להתייעץ בהנחיות היצרן לסוג המונה הספציפי ולדרישות היישום. ייתכן שחלק מהמונים ידרשו שיקולים מיוחדים או התאמות להתקנה אנכית.