mga device sa pagsukat ng pagpapatakbo

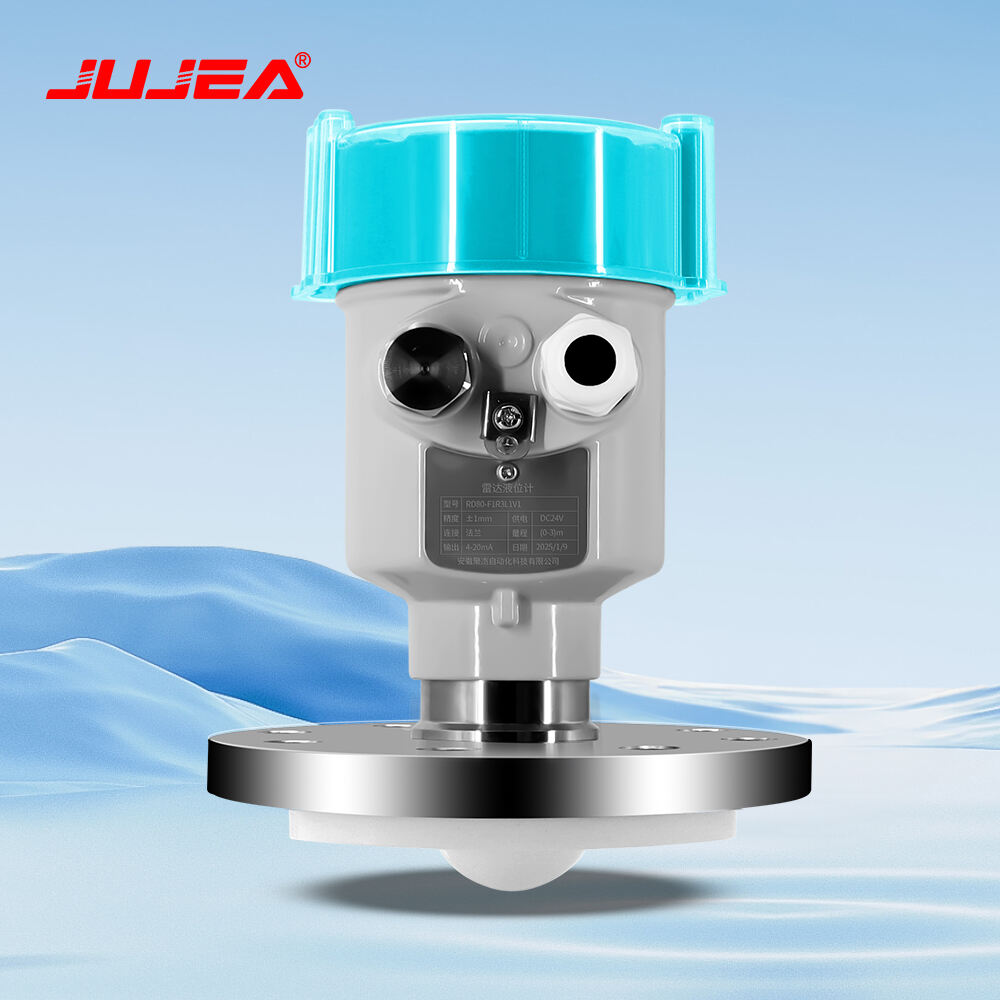

Ang mga instrumento sa pagsukat ng daloy ay sopistikadong mga gamit na idinisenyo upang tumpak na masukat at bantayan ang paggalaw ng likido, gas, o singaw sa loob ng mga tubo at kanal. Pinagsasama-sama ng mga mahahalagang gamit na ito ang makabagong teknolohiya ng sensor at eksaktong mga mekanismo ng kalibrasyon upang magbigay ng real-time na datos ng rate ng daloy, na nagpapaseguro ng optimal na kontrol sa proseso at pamamahala ng mga yaman. Ginagamit ng modernong mga instrumento sa pagsukat ng daloy ang iba't ibang prinsipyo, kabilang ang electromagnetic, ultrasonic, at differential pressure na paraan, upang maghatid ng tumpak na mga pagsukat sa iba't ibang aplikasyon sa industriya. Kasama sa mga tampok ng mga instrumentong ito ang digital na display, kakayahang i-record ang datos, at mga opsyon sa malayuang pagbantay, na ginagawa silang mahalaga sa mga industriya tulad ng chemical processing, water treatment, langis at gas, at pagmamanupaktura. Ang integrasyon ng matalinong teknolohiya ay nagpapahintulot sa automated na koleksyon ng datos, pagsusuri ng mga uso, at predictive maintenance, na nagpapataas ng kahusayan sa operasyon at binabawasan ang downtime. Sinasama rin ng mga instrumentong ito ang mga tampok na kompensasyon para sa temperatura at presyon, na nagpapanatili ng katumpakan sa iba't ibang kondisyon sa kapaligiran. Ang kanilang matibay na konstruksyon ay nakakatagal sa mapanganib na mga kapaligiran sa industriya habang pinapanatili ang tumpak na pagsusukat, na ginagawa silang maaasahang mga gamit parehong para sa kontrol sa proseso at pagtugon sa regulasyon.