In today's competitive industrial landscape, achieving optimal hydraulic system performance requires precise measurement and control of fluid flow rates. A reliable hydraulic oil flow meter serves as the cornerstone of efficient system operation, providing real-time data that enables operators to make informed decisions about maintenance, performance optimization, and energy consumption. Working with an experienced supplier can transform how industrial facilities approach hydraulic system management, offering not just equipment but comprehensive solutions that drive measurable improvements in operational efficiency.

The relationship between accurate flow measurement and system efficiency extends beyond simple monitoring. Modern hydraulic systems operate under demanding conditions where even minor inefficiencies can compound into significant operational costs over time. Professional suppliers understand these dynamics and offer integrated solutions that address multiple aspects of hydraulic system performance, from initial equipment selection to ongoing technical support and maintenance optimization.

Understanding Modern Hydraulic Flow Measurement Technology

Advanced Sensor Technologies and Their Applications

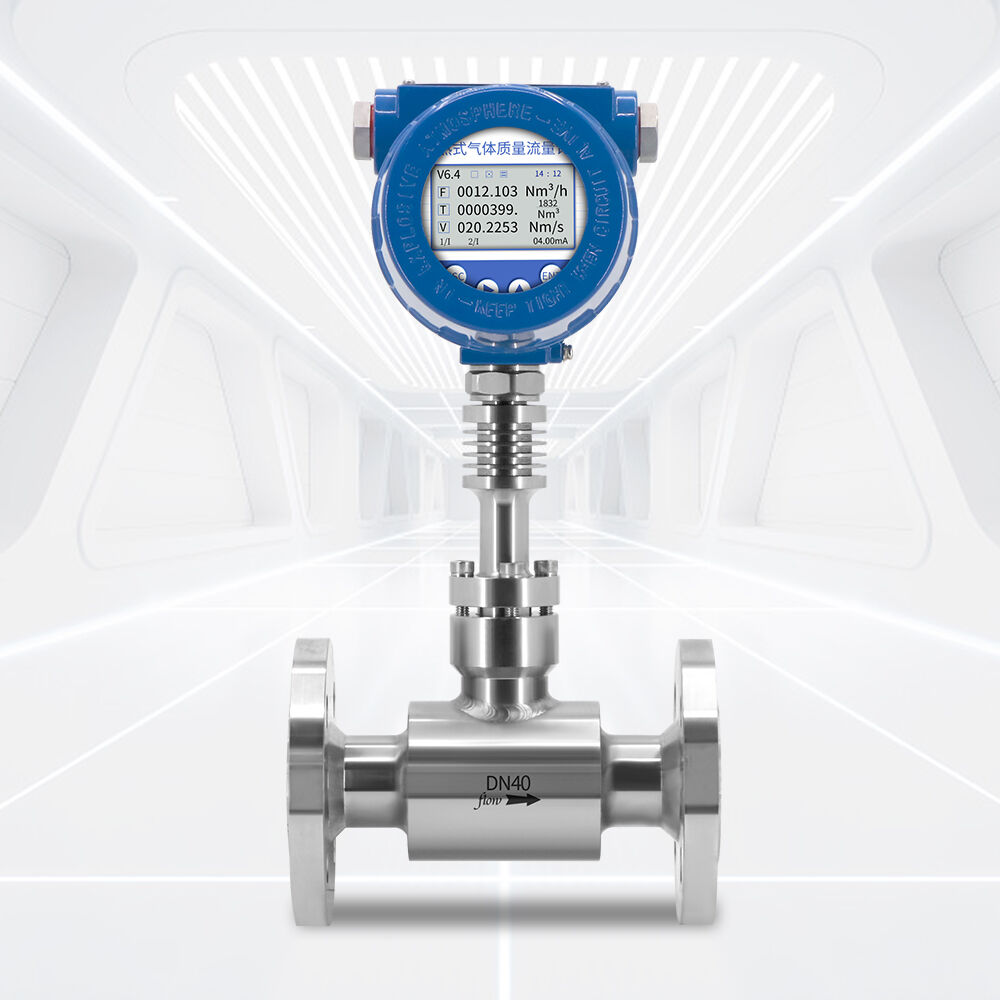

Contemporary hydraulic oil flow measurement relies on sophisticated sensor technologies that provide unprecedented accuracy and reliability. Oval gear meters, turbine flow meters, and electromagnetic flow meters each offer distinct advantages depending on specific application requirements. Professional suppliers evaluate factors such as fluid viscosity, temperature ranges, pressure conditions, and installation constraints to recommend the most suitable technology for each application.

The evolution of digital signal processing has enhanced measurement precision while reducing susceptibility to external interference. Modern flow meters incorporate advanced algorithms that compensate for temperature variations, pressure fluctuations, and fluid property changes, ensuring consistent accuracy across diverse operating conditions. This technological advancement enables more precise system control and facilitates predictive maintenance strategies that minimize unexpected downtime.

Integration Capabilities with Modern Control Systems

Today's hydraulic oil flow meters are designed for seamless integration with industrial automation systems and data acquisition platforms. Professional suppliers provide comprehensive connectivity solutions that enable real-time data transmission to supervisory control and data acquisition systems, programmable logic controllers, and cloud-based monitoring platforms. This integration capability transforms raw flow data into actionable intelligence that drives operational improvements.

The ability to correlate flow measurement data with other system parameters creates opportunities for advanced analytics and optimization strategies. When flow meters communicate effectively with pressure sensors, temperature monitors, and power consumption meters, operators gain comprehensive insights into system performance characteristics that would be impossible to achieve through isolated measurements.

Supplier Expertise in System Optimization Strategies

Comprehensive System Assessment and Analysis

Experienced suppliers bring valuable analytical capabilities to hydraulic system optimization projects. Through comprehensive system assessments, they identify inefficiencies, bottlenecks, and improvement opportunities that may not be apparent to facility operators. These assessments typically involve detailed flow pattern analysis, energy consumption evaluation, and performance benchmarking against industry standards.

The assessment process often reveals hidden inefficiencies such as internal leakage, excessive pressure drops, or suboptimal flow distribution patterns. Professional suppliers use advanced diagnostic tools and methodologies to quantify these losses and develop targeted improvement strategies. This analytical approach ensures that optimization efforts focus on areas with the highest potential for performance gains and return on investment.

Customized Solution Development and Implementation

Every hydraulic system presents unique challenges and optimization opportunities that require tailored solutions. Professional suppliers develop customized approaches that consider specific operational requirements, environmental conditions, and performance objectives. This customization extends beyond equipment selection to include installation procedures, calibration protocols, and ongoing maintenance strategies.

The implementation of hydraulic oil flow meter systems requires careful attention to installation details that can significantly impact measurement accuracy and system performance. Experienced suppliers provide detailed installation guidelines, conduct on-site commissioning, and verify system performance through comprehensive testing procedures that ensure optimal operation from the start.

Economic Benefits and Return on Investment

Energy Efficiency Improvements and Cost Savings

Accurate flow measurement enables significant energy savings through improved system efficiency and optimized operational parameters. By providing real-time visibility into flow patterns and consumption rates, hydraulic oil flow meters help operators identify opportunities to reduce energy waste, optimize pump operation, and minimize unnecessary system losses. These improvements often result in energy cost reductions of ten to twenty percent or more.

The ability to monitor and control flow rates precisely also enables implementation of demand-based control strategies that adjust system output to match actual requirements. This approach eliminates energy waste associated with oversized systems or excessive safety margins while maintaining adequate performance margins for critical applications. Professional suppliers help quantify these benefits and develop implementation strategies that maximize energy savings potential.

Maintenance Cost Reduction and Equipment Longevity

Proactive monitoring of hydraulic oil flow patterns provides early warning of developing problems that could lead to costly equipment failures or unplanned downtime. Flow measurement data reveals trends that indicate component wear, contamination issues, or system degradation before these problems become critical. This predictive capability enables maintenance teams to schedule repairs during planned outages, reducing emergency service costs and minimizing production disruptions.

Regular monitoring also helps optimize maintenance intervals and procedures based on actual system conditions rather than arbitrary schedules. Professional suppliers provide guidance on interpreting flow measurement data to develop condition-based maintenance strategies that extend equipment life while reducing maintenance costs. This approach often results in significant cost savings compared to traditional time-based maintenance programs.

Technical Support and Long-Term Partnership Benefits

Ongoing Technical Consultation and System Optimization

The relationship with a professional hydraulic oil flow meter supplier extends far beyond initial equipment delivery and installation. Ongoing technical support includes regular system performance reviews, optimization consultations, and assistance with evolving operational requirements. This long-term partnership approach ensures that flow measurement systems continue to deliver maximum value throughout their operational life.

Professional suppliers maintain detailed records of system performance and provide periodic analysis reports that identify trends, highlight optimization opportunities, and recommend improvement strategies. This ongoing engagement helps facilities stay current with technological advances and industry best practices while maximizing the return on their flow measurement investments.

Training and Knowledge Transfer Programs

Effective utilization of hydraulic oil flow meter systems requires proper training for operations and maintenance personnel. Professional suppliers provide comprehensive training programs that cover equipment operation, data interpretation, troubleshooting procedures, and maintenance best practices. This knowledge transfer ensures that facility personnel can maximize system benefits and maintain optimal performance over time.

Training programs typically include both theoretical instruction and hands-on experience with actual equipment. Professional suppliers often provide ongoing educational support through refresher courses, technical bulletins, and access to expert consultation services. This continuing education approach helps personnel stay current with evolving technologies and optimization strategies.

Future Trends and Technology Evolution

Digital Transformation and Smart Monitoring Solutions

The integration of Internet of Things technologies and artificial intelligence algorithms is transforming hydraulic oil flow measurement capabilities. Smart flow meters equipped with advanced analytics can identify patterns, predict maintenance needs, and automatically optimize system parameters without human intervention. Professional suppliers are at the forefront of these technological developments, helping customers leverage emerging capabilities to achieve new levels of efficiency.

Cloud-based monitoring platforms enable remote system oversight and advanced analytics that were previously impractical for many facilities. These platforms aggregate data from multiple locations, apply machine learning algorithms to identify optimization opportunities, and provide actionable recommendations through user-friendly dashboards. Professional suppliers help customers navigate this technological evolution and implement solutions that deliver measurable benefits.

Sustainability and Environmental Compliance

Growing emphasis on environmental responsibility is driving demand for more efficient hydraulic systems that minimize energy consumption and reduce environmental impact. Accurate flow measurement plays a crucial role in achieving sustainability objectives by enabling precise control of fluid usage, reducing waste, and optimizing energy consumption patterns.

Professional suppliers understand the relationship between flow measurement accuracy and environmental performance, helping customers develop strategies that meet sustainability goals while maintaining operational efficiency. This includes guidance on fluid recycling, contamination monitoring, and waste reduction strategies that support both economic and environmental objectives.

FAQ

What factors should be considered when selecting a hydraulic oil flow meter supplier?

Key selection criteria include technical expertise in hydraulic systems, breadth of product offerings, quality of technical support services, and track record of successful implementations. The supplier should demonstrate understanding of specific industry requirements and provide comprehensive solutions that extend beyond basic equipment supply to include system integration, training, and ongoing support services.

How quickly can flow measurement improvements impact system efficiency?

Many efficiency improvements become apparent immediately after installation and commissioning of accurate flow measurement systems. However, the full benefits typically develop over several months as operators learn to interpret data effectively and implement optimization strategies. Professional suppliers help accelerate this learning process through proper training and ongoing technical support.

What maintenance requirements are associated with modern hydraulic oil flow meters?

Modern flow meters are designed for minimal maintenance requirements, typically involving periodic calibration verification, sensor cleaning, and connection inspection. Professional suppliers provide detailed maintenance schedules and procedures tailored to specific applications and operating conditions. Many advanced systems include self-diagnostic capabilities that alert operators to maintenance needs before problems develop.

Can existing hydraulic systems be retrofitted with advanced flow measurement capabilities?

Most hydraulic systems can accommodate flow measurement retrofits with proper planning and execution. Professional suppliers conduct feasibility assessments to determine the best approach for each situation, considering factors such as space constraints, piping modifications, and integration requirements. Retrofit projects often provide excellent return on investment through improved efficiency and reduced operating costs.

Table of Contents

- Understanding Modern Hydraulic Flow Measurement Technology

- Supplier Expertise in System Optimization Strategies

- Economic Benefits and Return on Investment

- Technical Support and Long-Term Partnership Benefits

- Future Trends and Technology Evolution

-

FAQ

- What factors should be considered when selecting a hydraulic oil flow meter supplier?

- How quickly can flow measurement improvements impact system efficiency?

- What maintenance requirements are associated with modern hydraulic oil flow meters?

- Can existing hydraulic systems be retrofitted with advanced flow measurement capabilities?