The Crucial Role of Flowmeters in Liquid Flow Monitoring

Flowmeters serve as fundamental devices in managing and monitoring liquid flow across various industries. Their ability to provide precise, real-time measurement of flow rates is indispensable for optimizing process efficiency, ensuring safety, and maintaining regulatory compliance. The integration of flowmeters into liquid systems enables operators to track volumes accurately, detect leaks or blockages, and adjust processes dynamically. These instruments play a critical role not only in industrial applications but also in municipal water management, chemical processing, and food and beverage production. Understanding why a flowmeter is essential requires examining the multiple facets in which accurate flow measurement impacts operations and decision-making. The reliability and technological advancements of modern flowmeters further enhance their value, making them a cornerstone in liquid flow monitoring strategies.

Enhancing Process Control and Efficiency

Improving Accuracy in Flow Measurement

Achieving precise measurement of liquid flow is paramount for efficient process control. Flowmeters provide detailed information on the flow rate, enabling operators to regulate inputs and outputs with fine granularity. This accuracy helps optimize resource use, reduce waste, and improve product consistency. In industries where liquid components are critical, such as pharmaceuticals or chemicals, minor deviations in flow can lead to significant quality issues or safety hazards. Flowmeters support process automation by feeding data into control systems, ensuring that operational parameters remain within desired limits. With accurate flow data, managers can implement proactive adjustments that minimize downtime and improve throughput. The impact of precision flow measurement extends to cost savings, as better control reduces material loss and energy consumption.

Facilitating Real-Time Monitoring and Decision-Making

The ability to monitor liquid flow in real time is a distinct advantage offered by flowmeters. Continuous data collection allows operators to respond promptly to fluctuations or anomalies in flow rates. For instance, sudden drops or spikes may indicate leaks, blockages, or equipment malfunctions. Early detection through flowmeter readings prevents costly damage or operational disruptions. Real-time monitoring supports dynamic decision-making, enabling quick adjustments to maintain optimal performance. Furthermore, this immediate feedback loop improves safety by alerting personnel to potentially hazardous conditions before they escalate. Integration with digital dashboards and control systems means that flow data can be visualized, analyzed, and acted upon efficiently. This capability aligns with modern Industry 4.0 standards, promoting smart manufacturing and process transparency.

Ensuring Regulatory Compliance and Safety

Meeting Environmental and Industry Standards

Many industries operate under strict regulations that mandate accurate measurement and reporting of liquid flow. Flowmeters are essential tools in achieving compliance with environmental guidelines, safety codes, and quality standards. Accurate flow data ensures that processes adhere to permissible discharge limits, chemical dosing, or water usage restrictions. Regulatory bodies often require detailed records of flow measurements for audits or certification. Flowmeters provide reliable documentation that supports legal and environmental accountability. Failing to monitor flow adequately may lead to fines, shutdowns, or reputational damage. In sectors like wastewater treatment or chemical manufacturing, precise flow measurement protects ecosystems and public health by controlling pollutant release. Compliance-oriented flow monitoring promotes sustainable operations and corporate responsibility.

Preventing Hazards Through Accurate Measurement

Safety in liquid handling systems depends on the ability to detect and respond to irregular flow conditions. Flowmeters contribute by monitoring the flow of hazardous or reactive liquids, ensuring that rates remain within safe thresholds. Overflows, leaks, or unexpected stoppages can pose significant risks to personnel and infrastructure. Flowmeter data helps identify these issues early, triggering alarms or automated shutdowns. Additionally, flowmeters aid in verifying that safety protocols—such as emergency relief flows or containment system performance—are functioning correctly. Accurate flow measurement is vital in preventing accidents related to chemical exposure, flooding, or pressure build-up. By maintaining tight control over liquid flow, industries can protect workers, assets, and the environment.

Supporting Billing and Inventory Management

Accurate Measurement for Fair Billing

In utilities and commercial operations, flowmeters are critical for accurate billing based on liquid consumption or delivery. Whether in water supply, fuel distribution, or chemical sales, precise flow data ensures customers are charged fairly. Flowmeters eliminate guesswork and prevent revenue loss due to inaccurate estimation. Transparent billing supported by reliable measurement builds trust between providers and clients. Advanced flowmeters with digital communication enable remote reading and automated invoicing, improving operational efficiency. Accuracy in billing is particularly important for large-volume transactions where small measurement errors can translate into significant financial discrepancies. Flowmeters facilitate transparent, auditable transactions, supporting healthy business relationships and regulatory compliance.

Managing Inventory and Reducing Waste

Flowmeters provide detailed information that helps optimize inventory control for liquids in storage and process systems. Real-time flow measurement tracks consumption rates and remaining volumes, enabling precise inventory forecasting. This data helps avoid overstocking or shortages that disrupt operations. In manufacturing, flowmeters contribute to waste reduction by ensuring correct dosing and preventing spillage. Efficient inventory management driven by flowmeter data lowers carrying costs and minimizes environmental impact. Knowing exact flow rates helps schedule timely replenishment and optimize logistics. Flowmeter integration with inventory management software supports automated reordering and accurate record-keeping. The result is a leaner supply chain with enhanced profitability and sustainability.

Enabling System Diagnostics and Maintenance

Early Detection of System Anomalies

Flowmeters are valuable diagnostic tools for detecting abnormalities within liquid handling systems. Changes in flow patterns can signal leaks, blockages, pump failures, or valve malfunctions. By monitoring flowmeter data continuously, operators can identify issues before they cause major damage or downtime. This predictive maintenance approach reduces unplanned outages and repair costs. Flowmeters may also detect gradual wear or degradation of components by analyzing deviations from baseline flow profiles. Such insights support targeted maintenance and extend equipment life. Diagnostic capabilities of flowmeters improve system reliability and operational continuity, which are essential for industries with critical liquid processes.

Facilitating Preventive Maintenance Programs

Using flowmeter data, maintenance teams can schedule inspections and servicing more effectively. Preventive maintenance guided by accurate flow information helps maintain optimal system performance. Flowmeters provide benchmarks for normal operation, against which future measurements are compared. When deviations occur, maintenance actions can be planned proactively. This approach minimizes emergency repairs and maximizes equipment availability. Preventive maintenance informed by flowmeter analytics supports efficient resource allocation and reduces operational risks. Flowmeters integrated with digital maintenance management systems enhance transparency and communication among teams. By enabling data-driven maintenance strategies, flowmeters contribute to overall process excellence.

Adapting to Various Industry Applications

Versatility Across Different Liquids and Industries

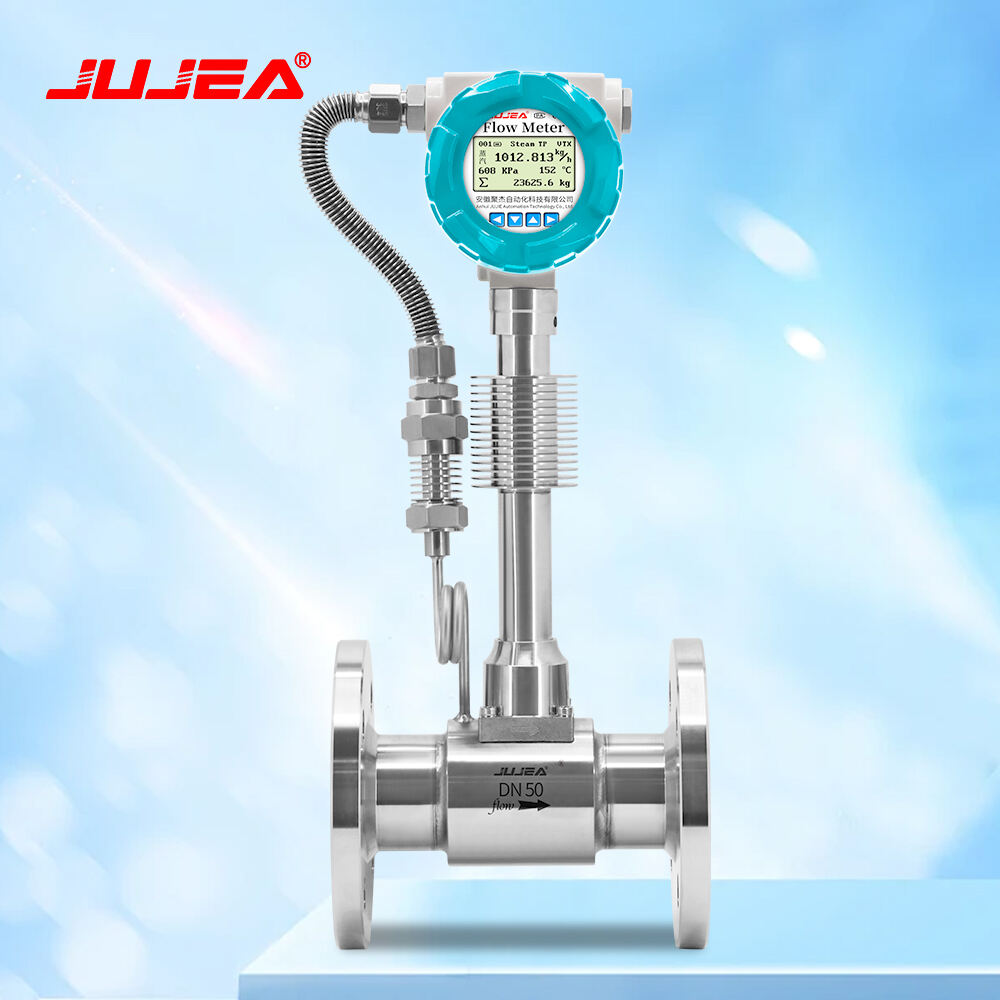

Flowmeters are designed to accommodate a wide range of liquid types, including water, chemicals, oils, and slurries. Their versatility makes them indispensable in diverse industries such as chemical processing, food and beverage, pharmaceuticals, water treatment, and oil and gas. Different flowmeter technologies—electromagnetic, ultrasonic, Coriolis, turbine, and more—offer tailored solutions based on fluid properties and application requirements. Selecting the appropriate flowmeter type ensures accurate measurement regardless of viscosity, temperature, or chemical composition. This adaptability supports consistent monitoring across challenging process conditions. Flowmeters’ broad applicability is a key reason for their widespread adoption in industrial and commercial liquid flow monitoring.

Customization for Specific Operational Needs

Manufacturers and operators can customize flowmeter features to meet unique process demands. Options include various sensor materials, sizes, communication protocols, and output signals. Flowmeters can be configured for high-pressure or corrosive environments, extreme temperatures, or sanitary conditions. This customization enhances measurement accuracy and device longevity. Integration with control systems and data networks allows for remote monitoring and advanced analytics. Custom features such as flow totalizers, alarms, and diagnostic functions provide additional operational benefits. Tailoring flowmeter specifications ensures optimal performance for particular liquids, flow ranges, and installation conditions. The ability to adapt flowmeters to specialized applications makes them essential tools in modern liquid management.

Cost-Effectiveness and Return on Investment

Reducing Operational Costs Through Accurate Flow Data

Accurate flow measurement helps reduce operational expenses by optimizing resource use and minimizing waste. Flowmeters prevent overuse of expensive liquids or additives and reduce energy consumption by improving process control. Early leak detection reduces product loss and environmental cleanup costs. Efficient dosing and blending based on flowmeter data improve product quality and reduce rework. These factors contribute to overall cost savings and increased profitability. The initial investment in quality flowmeters is offset by operational efficiencies and reduced downtime. Cost-effective flow monitoring supports sustainable business practices and enhances competitiveness in the market.

Increasing Productivity and Process Reliability

Flowmeters enhance productivity by providing reliable, timely flow information that enables continuous process optimization. Operators can quickly respond to changing conditions and maintain stable operations. Improved flow measurement reduces variability and ensures consistent product output. Flowmeters also facilitate automation, reducing manual intervention and associated errors. Enhanced process reliability leads to higher throughput and better customer satisfaction. The increased operational stability enabled by flowmeters supports scaling and innovation. Investing in accurate flow measurement technology is a strategic decision that drives long-term productivity gains.

Integration with Digital Technologies

Leveraging IoT and Smart Flowmeters

Modern flowmeters often come equipped with digital communication capabilities, supporting Internet of Things (IoT) integration. Smart flowmeters provide remote access, real-time alerts, and advanced analytics. This connectivity facilitates predictive maintenance, performance optimization, and energy management. IoT-enabled flowmeters enhance visibility across distributed assets and complex operations. They support data-driven decision-making and improve operational transparency. The adoption of smart flowmeter technology aligns with digital transformation initiatives across industries. Leveraging these capabilities maximizes the value of flowmeter data for operational excellence.

Enhancing Data Analytics and Process Insights

The rich data collected by advanced flowmeters enable detailed analysis of flow trends, anomalies, and system behavior. Integrating flowmeter outputs with analytics platforms reveals opportunities for process improvement and risk mitigation. Data visualization helps operators understand complex flow dynamics and optimize system design. Advanced analytics also support regulatory reporting and quality assurance. Flowmeter data serves as a foundation for continuous improvement programs and innovation. Harnessing the power of data enhances flowmeter utility beyond simple measurement, transforming liquid flow monitoring into a strategic asset.

FAQ

Why is flowmeter accuracy important in liquid flow monitoring

Accurate flowmeter readings ensure precise process control, safety, compliance, and billing. Inaccurate data can lead to product quality issues, safety hazards, and financial losses.

How do I choose the right flowmeter for my liquid application

Consider fluid properties, flow range, installation conditions, and required accuracy. Matching the flowmeter type to specific application needs maximizes measurement reliability.

What maintenance is needed to keep a flowmeter accurate

Regular inspection, cleaning, calibration, and monitoring for wear or damage preserve flowmeter accuracy and extend service life. Preventive maintenance reduces unexpected failures.

Can digital flowmeters improve liquid flow monitoring efficiency

Yes, digital flowmeters with IoT capabilities enable real-time monitoring, predictive maintenance, and advanced analytics, enhancing operational visibility and decision-making.

Table of Contents

- The Crucial Role of Flowmeters in Liquid Flow Monitoring

- Enhancing Process Control and Efficiency

- Ensuring Regulatory Compliance and Safety

- Supporting Billing and Inventory Management

- Enabling System Diagnostics and Maintenance

- Adapting to Various Industry Applications

- Cost-Effectiveness and Return on Investment

- Integration with Digital Technologies

- FAQ