Understanding Which Factors Influence Flowmeter Accuracy

Flowmeter performance depends on multiple factors that influence measurement precision and consistency. Key elements such as fluid properties, installation conditions, calibration procedures, equipment type, and environmental variables combine to determine real-world accuracy. Even small deviations in pipe alignment or fluid temperature can cause significant measurement error. Proper sensor selection, consistent calibration schedules, and understanding each meter’s operational envelope are essential. Engineers must match flowmeter types with specific application conditions and verify performance under expected ranges. Regular maintenance, clean piping, and proper program logic help preserve accuracy over time. If carefully managed, flowmeter installations can deliver reliable measurements within specified tolerances, supporting process control, safety, billing, and compliance needs.

Fluid Characteristics and Their Effects on Accuracy

How Fluid Viscosity and Composition Influence Readings

Viscosity impacts how fluids interact with flowmeter mechanisms, particularly in mechanical meters or positive displacement types. Higher viscosity slows flow profile development and may cause drag on moving parts, leading to under-registration in certain applications. Fluid with suspended solids or gas bubbles can interfere with ultrasonic or electromagnetic meters, affecting echo detection or magnetic damping. Chemical composition—such as conductivity or corrosiveness—also determines which flowmeter materials and technologies suit the application. Installation must consider fluid temperature, density, and particulate load to ensure accurate measurement. Temperature compensation or clean fluid conditioning may be required to maintain calibration over time. Understanding these fluid factors helps engineers choose flowmeters less sensitive to viscosity or particulate influences, achieving higher reliability in field conditions.

Impact of Fluid Flow Profile on Measurement Precision

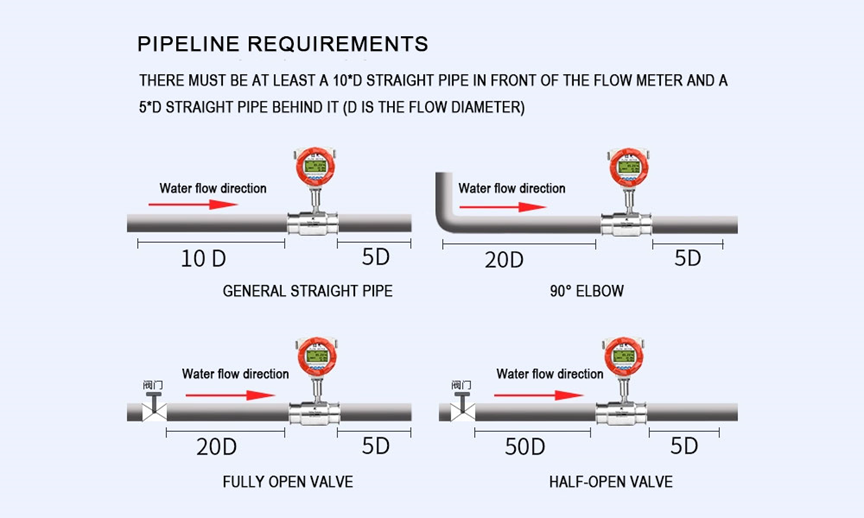

Accurate flow measurement requires a stable, fully developed flow profile entering the meter’s sensing zone. Upstream disturbances from elbows, valves, or pumps cause turbulence or swirl, degrading accuracy. Many manufacturers specify minimum straight-run lengths before and after the meter to stabilize flow. Turbulent conditions or swirl impair sensors based on differential pressure, ultrasonic transit time, or vortex shedding by altering turbulence frequency. Laminar profiles differ in signal signature and may produce offset readings if the device assumes turbulent flow. Operators should follow installation guidelines to ensure sufficient upstream and downstream piping, avoiding offsets caused by partial thickness or unbalanced flow. Attention to flow conditioning components like straighteners or flow blankets can reduce error. Optimizing flow entry conditions significantly improves flowmeter performance and repeatability.

Installation and Piping Configuration Matters

Tube Alignment, Straight-Run Requirements, and Positioning

Proper flowmeter installation depends on adequate length of straight piping flanking the meter. For many flowmeter types, recommended upstream lengths of 10 to 15 pipe diameters and downstream lengths of 5 to 10 diameters are standard. Deviating from guidelines introduces flow turbulence or swirl that affects sensor response consistency. Misalignment of insertion sensors or incorrect mounting angles on clamp-on ultrasonic meters causes echo timing errors. Elevation changes or vertical piping may trap air pockets around flow sensors, causing signal disruption or pressure shift. Engineers must ensure proper orientation and alignment, hang supports for meter bodies, and avoid insertion into partially full pipes or sloped lines. Incorrect installation increases measurement uncertainty and maintenance frequency due to blockages or drift.

Impact of Vibration, Pressure Pulsation, and Mechanical Noise

Flowmeters mounted near pumps, compressors, or vibrating machinery may register false pulses or echo fluctuations. Differential pressure or vortex meters are sensitive to pressure pulsation, which can introduce noise into analog signals. Ultrasonic transit-time sensors may misinterpret mechanical vibrations as flow signals. Mechanical noise can degrade signal-to-noise ratio, reducing measurement resolution. Mitigation includes using vibration isolators, mounting hangers, and upstream buffers to dampen pulsation. Pressure pulsation dampeners or stabilizing chambers may be needed to maintain steady gauge pressure. Flowmeter outputs should be routed through filters or signal conditioners to smooth out noise. Preventing mechanical interference directly supports consistent flowmeter accuracy and data reliability.

Calibration Practices and Their Importance

Establishing Accurate Calibration Baselines

Calibration is essential to align a flowmeter’s readout with true volumetric or mass flow. Baseline calibration involving known flow rates and reference standards like calibration rigs or master meters ensures initial accuracy. These calibrations should be performed at multiple flow points across operational ranges. Environmental conditions like temperature and pressure during calibration should reflect plant operating conditions. Calibration curves are stored in the flowmeter’s firmware or remote transmitter units. Site validation checks confirm that factory calibration remains valid after installation. Regular recalibration cycles—annual or semi-annual depending on application—help catch drift early. Documenting calibration data improves traceability and supports compliance. Without rigorous calibration protocols, flowmeter accuracy degrades over time, potentially harming process control or billing integrity.

Accounting for Drift, Wear, and Recalibration Scheduling

Flowmeters can drift due to sensor aging, erosion, or internal mechanical wear. Positive displacement meters may suffer from gear tooth wear; turbine meters may lose accuracy as blades erode; ultrasonic sensor alignment may shift. An accelerated drift schedule for harsh environments—high solids, corrosive chemicals, or thermal cycling—is recommended. Periodic verification and recalibration prevent long-term deviation from acceptable error thresholds. Software-based diagnostics in meters with self-check capability help detect anomalies before they affect output. Integration with SCADA or maintenance scheduling can automate alerts for recalibration. Well-defined drift thresholds help determine when meters should be serviced or replaced, maintaining data integrity. Proactive calibration management reduces unplanned downtime and ensures long-term measurement consistency.

Meter Type and Design Suitability

Selecting Flowmeter Types Based on Application Needs

Choosing the right flowmeter type is critical for measurement accuracy. Different technologies suit various fluid conditions: electromagnetic meters work for conductive liquids, while Coriolis flowmeters excel in dense, viscous fluids with high precision. Ultrasonic transit-time types suit clean, non-aerated streams and clamp-on accessibility. Vortex meters perform best on clean gases and steam. Differential pressure meters or orifice plates suit cost-sensitive bulk flows but require careful piping design. Positive displacement meters suit low flow or viscous liquids. Each meter type has inherent accuracy specs defined under ideal conditions. Selecting the correct type for actual fluid, temperature, and dynamic range ensures measurement remains within intended tolerance.

Understanding Range Limits and Turndown Ratios

Every flowmeter has a specified span or turndown ratio definining the low-to-high flow range at which accuracy is maintained. Using a meter near its lower limit may cause noisy readings or zero instability; operating at high rates may saturate the sensor or overload signal processors. For example, a Coriolis meter may offer 100:1 turndown, whereas a vortex meter may only achieve 20:1. Engineers need to match meter to flow range so that typical operating conditions fall well within the domain of highest accuracy. Meters with wide turndown ratios reduce the need for multiple devices across different flow stages. Understanding a flowmeter’s design envelope helps avoid systematic under- or over-reading errors due to operating out of specification.

Environmental Conditions and Signal Influence

Temperature, Pressure, and Ambient Influences

Fluid temperature affects density and viscosity, influencing flow velocity and calibration curves. Some meters measure volumetric flow and require compensation to calculate mass flow accurately. Pressure fluctuations can alter density, affecting velocity-to-volumetric conversions. Environmental temperature may also influence electronics or sensor transducers. Advanced flowmeters include temperature and pressure sensors to correct raw output automatically. Failing to account for ambient influences may cause greater than 1–2% error. Flowmeter signal stability requires consideration of seasonal or diurnal temperature changes. Calibration under representative conditions ensures field accuracy. Proper environmental compensation supports reliable performance under varying operating conditions.

Electromagnetic and Flow Interference Effects

Industrial environments often generate electromagnetic interference (EMI) from motors, drives, or radio sources. Flowmeters with electronic transmitters require proper cable shielding and grounded installation to avoid signal distortion. Ultrasonic and electromagnetic meters can be sensitive to stray magnetic fields or radio waves. Positioning signal cables away from power lines and using shielded conduit prevents such interference. Flow turbulence from upstream mixing or parallel lines can impact flow readings. Calibration included during installation allows detection of resonance or signal crosstalk. Minimizing interference sources is essential for consistent flowmeter accuracy and measurement integrity.

Maintenance Practices That Preserve Accuracy

Regular Cleaning, Inspection, and Preventive Care

Flowmeters operating in fluids with deposits, scaling, or particulates benefit from scheduled cleaning. Orifice plates should be checked for plate erosion or plugging; turbine impellers need inspection for wear; ultrasonic clamp-on sensors require clean coupling surfaces. Routine maintenance preserves signal clarity and prevents gradual accuracy loss. Visual inspection of meter components such as glass tubes, gauges, or alignment marks helps detect early failure. Preventive maintenance plans should align with process uptime schedules. Quick access ports or bypasses can enable sensor cleaning without process interruption. Comprehensive cleaning and inspection routines extend flowmeter lifespan and preserve accuracy over time.

Spare Parts Management and Component Alignment

Maintaining inventory of replacement parts—such as floats, orifice plates, seals, or sensors—ensures swift repairs. Using genuine components avoids misalignment or calibration shift upon replacement. Technicians should follow manufacturer alignment procedures when replacing parts to avoid introducing error. Documented maintenance procedures and staff training on proper assembly are essential. Component tolerance must match original calibrated geometry. Proper reassembly supports repeatable performance after service. Spare parts management reduces downtime and prevents long-term accuracy degradation. Detailed manuals and training maintain calibration integrity across service intervals.

System Integration and Calibration Feedback

Using Control System Feedback for Accuracy Monitoring

Flowmeter output integrated into SCADA, PLC, or DCS systems enables continuous validation of flow readings against expected operational patterns. Trend analysis helps detect anomalies such as drift or blockage. Automated comparisons between multiple flow points can identify leakage or calibration error. Control systems can issue alerts or initiate calibration if readings deviate from predictive models. Feedback loops support continuous improvement. Data-driven calibration scheduling increases measurement consistency across the plant. Integrating flowmeter signals into higher-level controls minimizes human error and enhances process efficiency.

Leveraging Historical Data for Calibration and Optimization

Maintaining logs of flowmeter readings over time provides insight into long-term deviations or drift patterns. Historical data helps determine when recalibration or sensor replacement is necessary. Post-event analysis reveals whether measurement anomalies correlate with process changes or equipment wear. Insights guide optimization of flowmeter placement or selection. Leveraging data supports predictive maintenance, reducing unnecessary calibration cycles. It also supports continuous process improvement initiatives. Using historical flow profiles as baseline benchmarks improves overall system reliability and flow measurement accuracy.

FAQ

What factors most significantly affect flowmeter accuracy

Fluid properties flow profile installation alignment meter type calibration quality environmental conditions and maintenance practices all significantly impact flowmeter measurement precision.

How often should flowmeters be recalibrated for accurate readings

Recalibration frequency depends on manufacturer guidelines fluid characteristics operational criticality and observed drift Typically calibration every six to twelve months is recommended unless diagnostics indicate earlier intervention.

Can changing temperature or pressure degrade flowmeter accuracy

Yes temperature and pressure affect fluid density viscosity and sensor electronics Modern flowmeters include built‑in compensation but proper calibration and environmental monitoring ensure maintained accuracy.

How can installation errors compromise flowmeter performance

Incorrect straight-run piping misalignment vibration EMI poor mounting or obstructed flow paths introduce turbulent or noisy signals leading to inaccuracy Proper installation following manufacturer guidance preserves flowmeter precision.

Table of Contents

- Understanding Which Factors Influence Flowmeter Accuracy

- Fluid Characteristics and Their Effects on Accuracy

- Installation and Piping Configuration Matters

- Calibration Practices and Their Importance

- Meter Type and Design Suitability

- Environmental Conditions and Signal Influence

- Maintenance Practices That Preserve Accuracy

- System Integration and Calibration Feedback

- FAQ