ultrasound-tasmitta

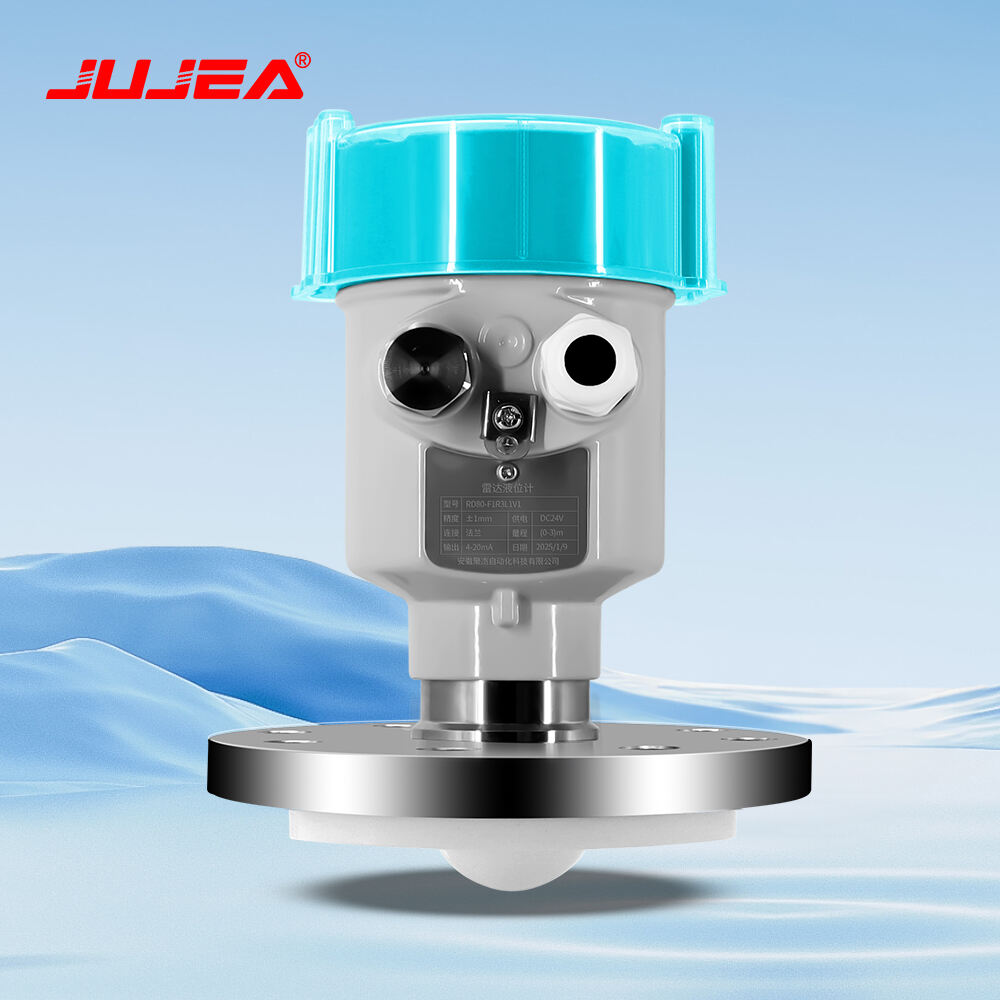

Ääniaaltotason mittari on edistynyt mittalaitteisto, joka käyttää ääniaaltoja määrittääkseen nestemäisten tai kiinteiden materiaalien tasoja erilaisissa säiliöissä ja astioissa. Toimiakseen laite perustuu etu- ja takaisinjuoksun mittausperiaatteeseen, jossa korkeataajuisia äänipulsseja lähettetään, ne heijastuvat mitattavan materiaalin pinnasta takaisin anturiin. Tämän kierroksen kesto lasketaan tarkasti määritettäessä etäisyyttä ja sitä kautta materiaalin tasoa. Näihin mittareihin on suunniteltu edistynyttä signaalinkäsittelytekniikkaa, joka takaa tarkan mittauksen myös haastavissa teollisuusympäristöissä. Laitteen ei-kosketusmittausmenetelmä tekee siitä erityisen arvokkaan sovelluksissa, joissa materiaalit ovat syövyttäviä, myrkyllisiä tai viskooseja ja joissa kosketusanturit saattaisivat epäonnistua tai rapistua. Nykyaikaisiin ääniaaltotason mittareihin kuuluu lämpötilakompensaatiomekanismeja, jotka ylläpitävät tarkkuutta vaihtelevissa olosuhteissa, ja niissä on älykkäitä algoritmeja, jotka suodattavat pois vääriä kaihoja sisäisistä rakenteista tai sekoituksista. Ne tarjoavat yleensä useita lähtövaihtoehtoja, kuten 4–20 mA -signaaleja, digitaalisia viestintäprotokollia ja paikallisia näyttöjä, mikä tekee niistä monikäyttöisenä integroitavia erilaisiin ohjausjärjestelmiin. Teknologiaa käytetään laajasti teollisuuden aloilla, vedentreatment-laitoksista kemiallisiin prosessointitehtaisiin ja elintarviketeollisuuteen, joissa luotettava tason mittaaminen on keskeistä prosessien ohjauksessa ja varastonhallinnassa.