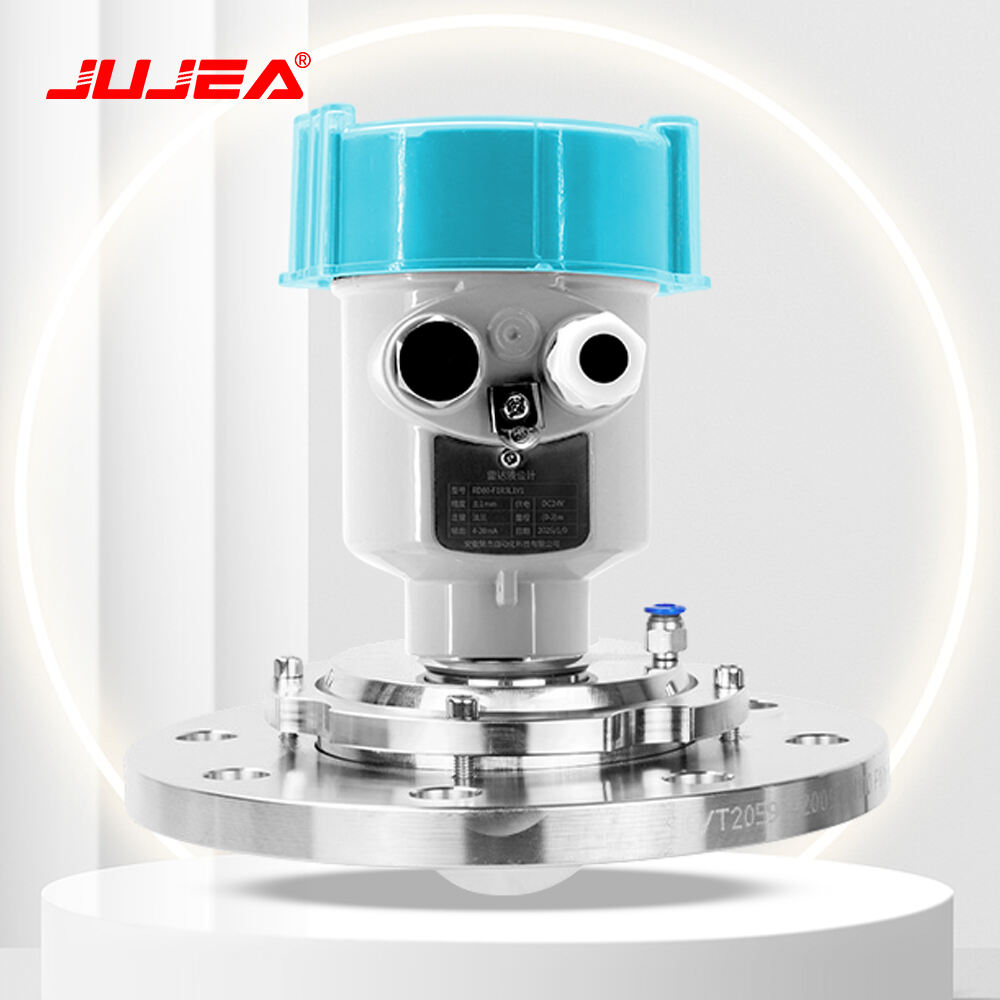

sensóir leibhéal tancach fuaimneartach

Is réiteach ardfheidhmeach é an t-sensóir leibhéal loisce ultraglas a chinneann leibhéal na leigheas go cruinn i roinnt tionscail éagsúla. Oibríonn an gléas seo trí tonnanna gréine ard-mhéidithe a sheoladh a bhuailfidh ar dhroim an uisce agus a fillfidh ar an sensóir. Trí thiomhas a chur ar an am a gcaillfidh na tonnanna seo chun taisteal, ríomhann an tsensóir an leibhéal cruinn den leigheas laistigh den tanc. Bainfidh an teicneolaíocht úsáid as próiseáil shiombail dhigiteach chun cur isteach a chosc agus cinntiú léargas éifeachtach faoi staid chleithe éagsúla. Tá na sensóirí seo deartha chun oibriú le raon ballaí leathan leigheas, lena n-áirítear uisce, ceimiceáin, agus oil, rud a dhéanann iad in uirlisí éagsúla do rialú prósais tionsclaigh. Bainfidh an prionsabal tomhais neamh-teagmhálta uair is féidir leigheas a chothromú agus laghdaíonn sé riachtanais coiscirt, mar níl páirtí gluaiseachta ann a bhfuil díreach téipthe leis an meán tomhais. Cuireann sensóirí ultraglas clúdaithe teochta le chéile chun cruinneas a choimeád ar feadh na gcónaí éagsúla. Mar gheall arna ionracas go minic, tá siad cruthaithe go daingean le rátáil cosc IP67 nó airde, ag cinntiú oibriú éifeachtach san amshuí tionsclaigh. Is féidir le raon tomhais an tsensóra a bheith ó lúchásanna beaga go dtí méadair iliomad, ag freastal ar thancaí de mhéid éagsúil. Déanann comhoibriú le córas rialaitheaimh na linne tríd na prótacail tionsclaigh caighdeánacha cosúil le 4-20mA, HART, nó Modbus a dhéanann na sensóirí seo in iarracht ríthábhachtach i gcórais rialaitheaimh uathoibríocha.