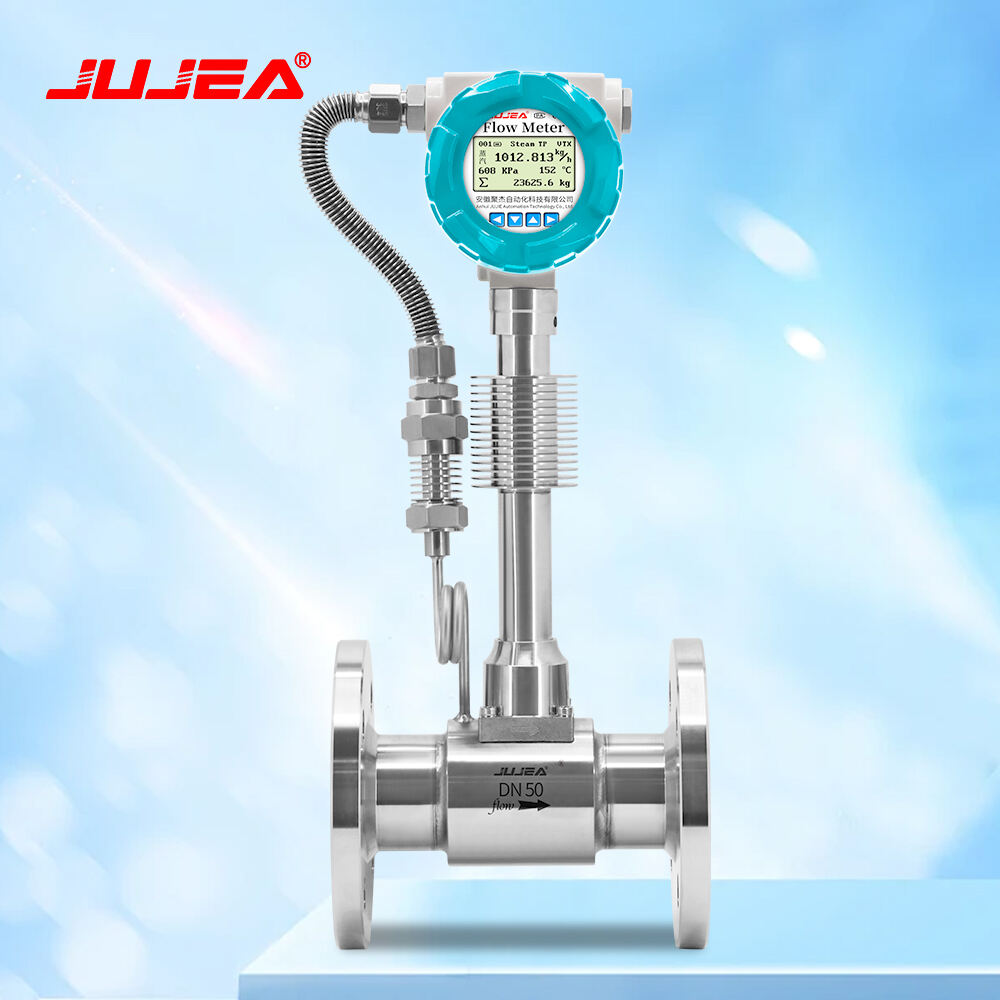

flow meter vortex

Sebuah flow meter vortex adalah instrumen pengukur yang canggih dirancang untuk menentukan secara akurat laju aliran fluida dalam berbagai aplikasi industri. Perangkat inovatif ini bekerja berdasarkan prinsip vortex shedding, di mana aliran fluida yang melewati sebuah bluff body menciptakan vortex yang bergantian. Frekuensi vortex tersebut berbanding lurus dengan kecepatan aliran, memungkinkan pengukuran yang tepat. Perangkat ini terdiri dari badan sensor, elektronik pemroses sinyal, dan antarmuka keluaran yang memberikan data aliran secara real-time. Flow meter vortex modern dilengkapi fitur canggih seperti pemrosesan sinyal digital, kompensasi suhu, dan self-diagnostics untuk memastikan kinerja yang andal di berbagai kondisi operasional. Alat-alat ini unggul dalam mengukur aliran cairan maupun gas, menjadikannya alat serbaguna di industri seperti pengolahan kimia, pembangkit listrik, dan pengolahan air. Konstruksinya yang kuat, biasanya menggunakan komponen baja tahan karat dan tanpa bagian bergerak, memastikan ketahanan jangka panjang dan kebutuhan perawatan minimal. Teknologi ini juga dapat menyesuaikan berbagai ukuran pipa serta mampu menangani berbagai rentang laju aliran, suhu, dan tekanan, menjadikannya solusi sangat adaptif untuk kebutuhan pengukuran aliran industri.