유량계: 액체 유량계의 차이점은 무엇이며 어떻게 선택해야 하나요?

현대 산업에서 유량 측정의 필수적인 역할 이해

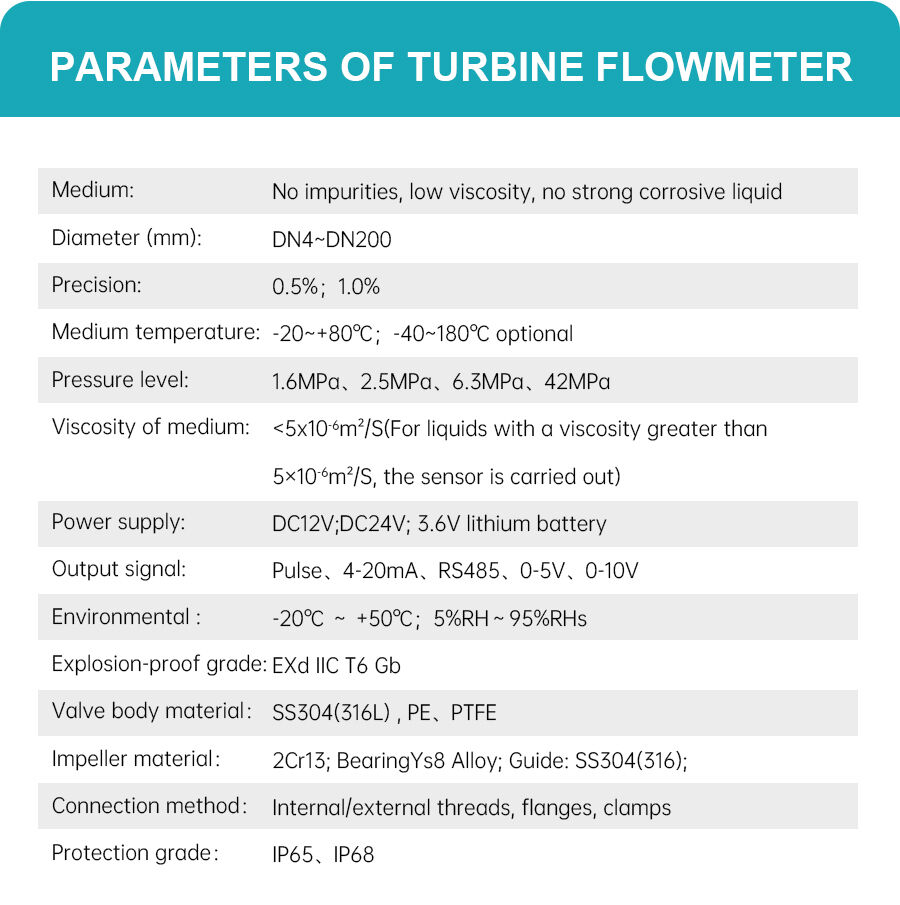

유량 측정 기술은 다양한 산업 공정의 핵심에 있으며, 액체 유량계는 다양한 응용 분야에서 없어서는 안 될 도구입니다. 정밀...

더 보기

Copyright © 2015 Anhui Jujie Automation Technology Co.,LTD. All rights reserved. | 개인정보 보호정책