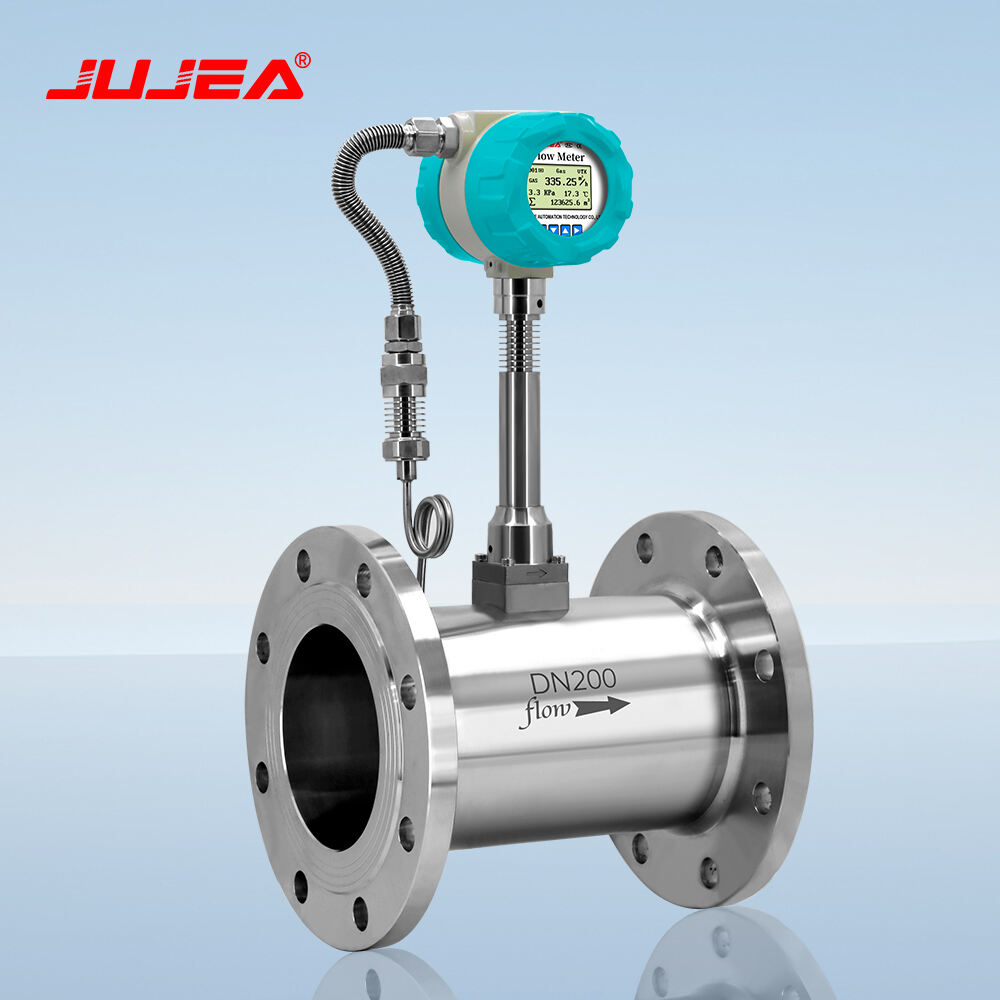

current flow meter

The current flow meter represents a cutting-edge solution for precise fluid measurement across various industrial applications. This advanced instrument utilizes electromagnetic principles to accurately measure the flow rate of conductive liquids, providing real-time monitoring and data collection capabilities. The device features a robust design with no moving parts, significantly reducing maintenance requirements while ensuring long-term reliability. It incorporates state-of-the-art sensing technology that enables measurements across a wide range of flow rates, from minimal to maximum capacity, with exceptional accuracy levels of up to 0.5%. The meter's innovative design includes a digital display interface that provides clear readings and allows for easy configuration and calibration. It supports multiple communication protocols, including HART, Modbus, and Foundation Fieldbus, enabling seamless integration with existing control systems. The flow meter's construction typically features corrosion-resistant materials, making it suitable for harsh industrial environments and compatible with various liquid types, including water, chemicals, and slurries. Advanced signal processing algorithms ensure stable measurements even under challenging conditions, while built-in diagnostics continuously monitor system health and performance.