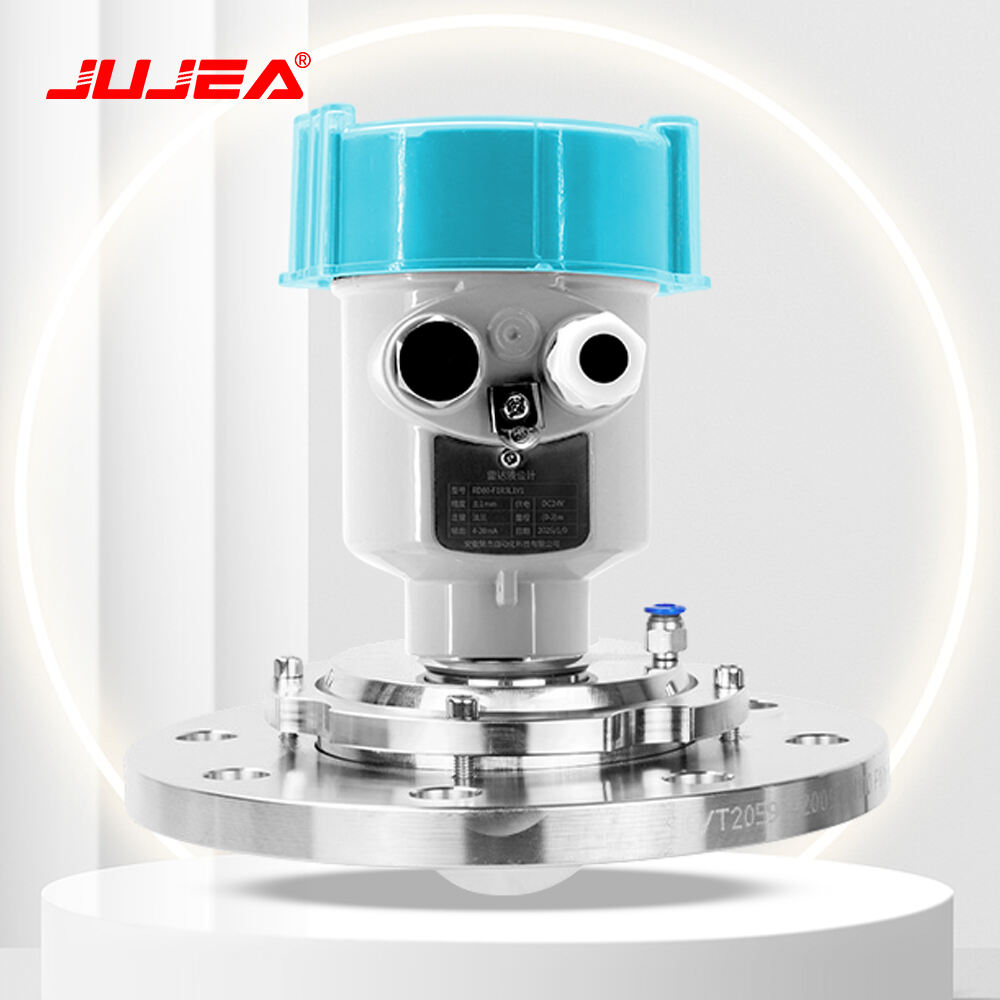

ikke-kontakt nivåsensor

Sensorer for nivåmåling uten kontakt representerer en moderne løsning innen industriell måleteknologi, og tilbyr nøyaktig overvåking av væsker og faste stoffer uten direkte fysisk kontakt med det målte stoffet. Disse sofistikerte enhetene benytter ulike sensorteknologier, som ultralyd, radar eller laserbasert måling, for å nøyaktig bestemme materialnivåer i beholdere, tanker og siloer. Ved å sende ut signaler og måle tiden det tar før de reflekteres tilbake fra materialoverflaten, beregner sensorene nøyaktige nivåverdier med bemerkelsesverdig presisjon. Teknologien inneholder avanserte signalbehandlingsfunksjoner for å filtrere bort støy og sikre pålitelige målinger selv i krevende industrielle miljøer. Sensorer for nivåmåling uten kontakt er ideelle for anvendelser som spenner over avløpsrenseanlegg, kjemiske prosesseringsanlegg og mat- og drikkevareproduksjon, hvor det er avgjørende å opprettholde produktkvalitet og utstyrssikkerhet. Fleksibiliteten til disse sensorene strekker seg til å kunne måle ulike materialer, inkludert korrosive stoffer, klistermaterialer og bulkfaststoff, samtidig som målenøyaktighet og systempålitelighet opprettholdes. De kan fungere effektivt under ekstreme temperaturer, i høytrykksmiljøer og på steder med intens elektromagnetisk interferens, noe som gjør dem uunnværlige i moderne industrielle prosesser.