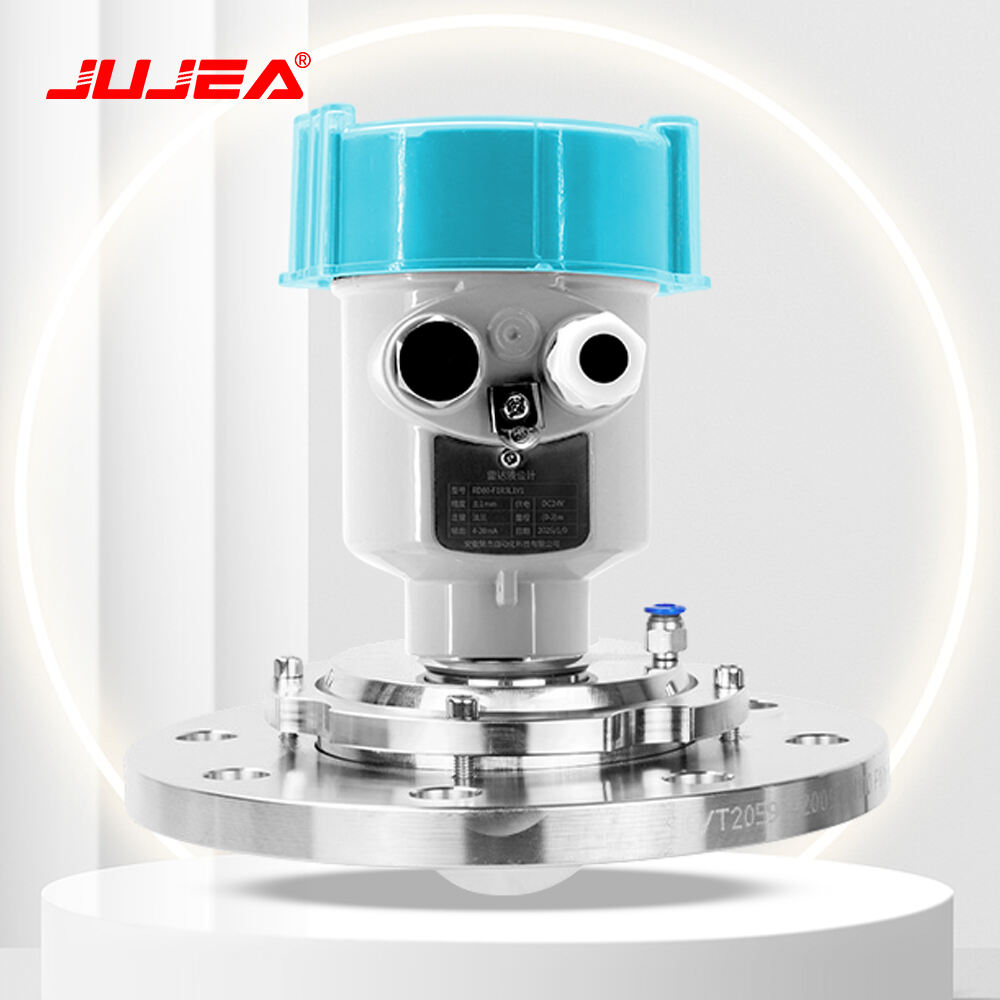

non contact level sensor

Non contact level sensors represent a cutting-edge solution in industrial measurement technology, offering precise liquid and solid level monitoring without direct physical contact with the measured substance. These sophisticated devices utilize various sensing principles, including ultrasonic waves, radar technology, or laser measurements, to accurately determine material levels in containers, tanks, and silos. Operating through the emission and reception of signals, these sensors measure the time taken for the signal to bounce back from the material surface, calculating the exact level with remarkable precision. The technology incorporates advanced signal processing capabilities to filter out interference and ensure reliable readings even in challenging industrial environments. These sensors excel in applications ranging from water treatment facilities and chemical processing plants to food and beverage manufacturing, where maintaining product quality and equipment integrity is paramount. The versatility of non contact level sensors extends to their ability to measure various materials, including corrosive substances, sticky materials, and bulk solids, all while maintaining measurement accuracy and system reliability. They can operate effectively in extreme temperatures, high-pressure environments, and locations with intense electromagnetic interference, making them indispensable in modern industrial processes.