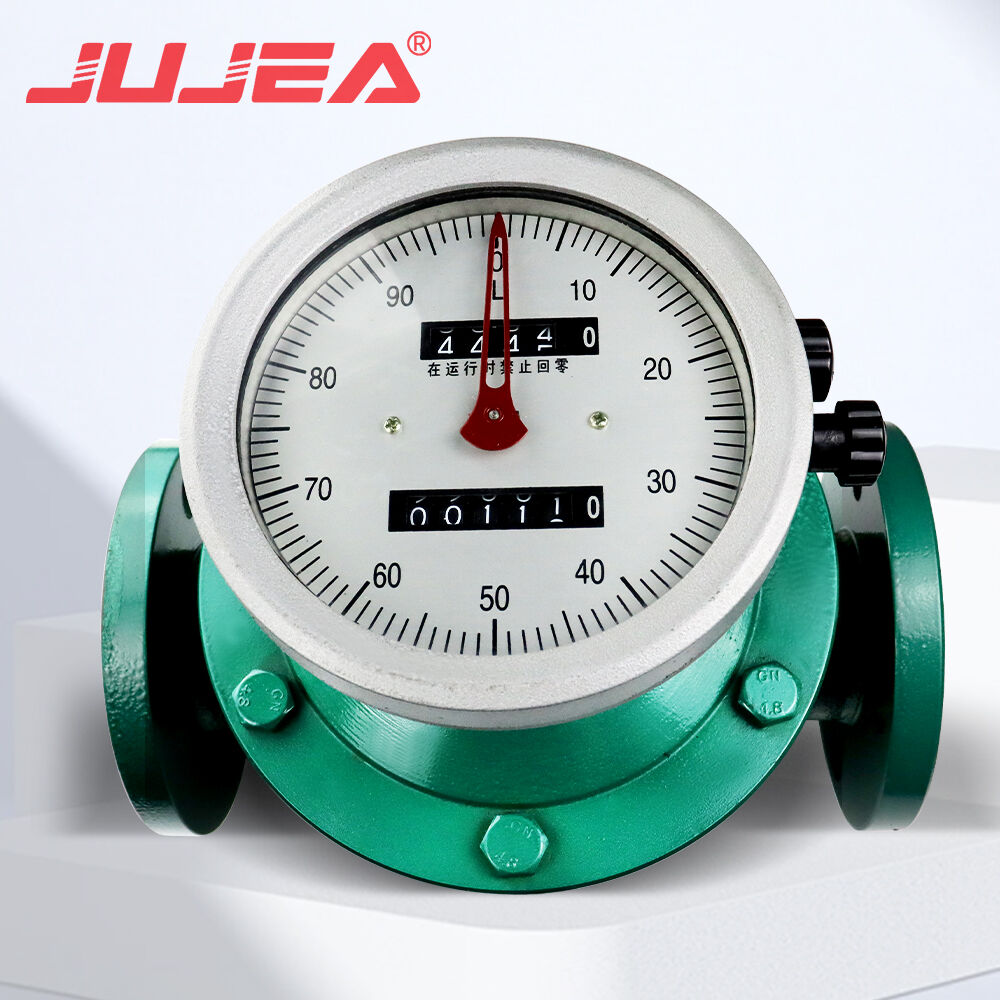

medidor de vazão tipo turbina

O medidor de vazão do tipo turbina representa um dispositivo sofisticado de medição projetado para mensurar com precisão a taxa de vazão de fluidos em diversas aplicações industriais. Este instrumento de precisão opera com base em um princípio simples, porém eficaz: à medida que o fluido passa pelo medidor, ele aciona um rotor de turbina, cuja velocidade de rotação está diretamente relacionada à vazão. O equipamento possui pás de turbina mecanizadas com precisão montadas em um rotor sustentado por rolamentos, acompanhadas por sensores magnéticos ou detectores eletrônicos que convertem a rotação mecânica em sinais elétricos mensuráveis. Esses medidores se destacam em aplicações que exigem alta precisão, especialmente na medição de líquidos limpos e de baixa viscosidade, como água, hidrocarbonetos e fluidos criogênicos. A tecnologia incorpora capacidades avançadas de processamento de sinal, permitindo monitoramento em tempo real da vazão e registro de dados. Os medidores modernos de vazão por turbina frequentemente incluem recursos de compensação de temperatura e correção de pressão, garantindo precisão nas medições sob diferentes condições operacionais. A construção robusta, geralmente fabricada em aço inoxidável ou ligas especiais, assegura durabilidade e confiabilidade em ambientes industriais exigentes. Esses medidores são amplamente utilizados nas indústrias de refino de petróleo, fabricação química, geração de energia e tratamento de água, onde a medição precisa da vazão é crucial para controle de processo e fins de faturamento.