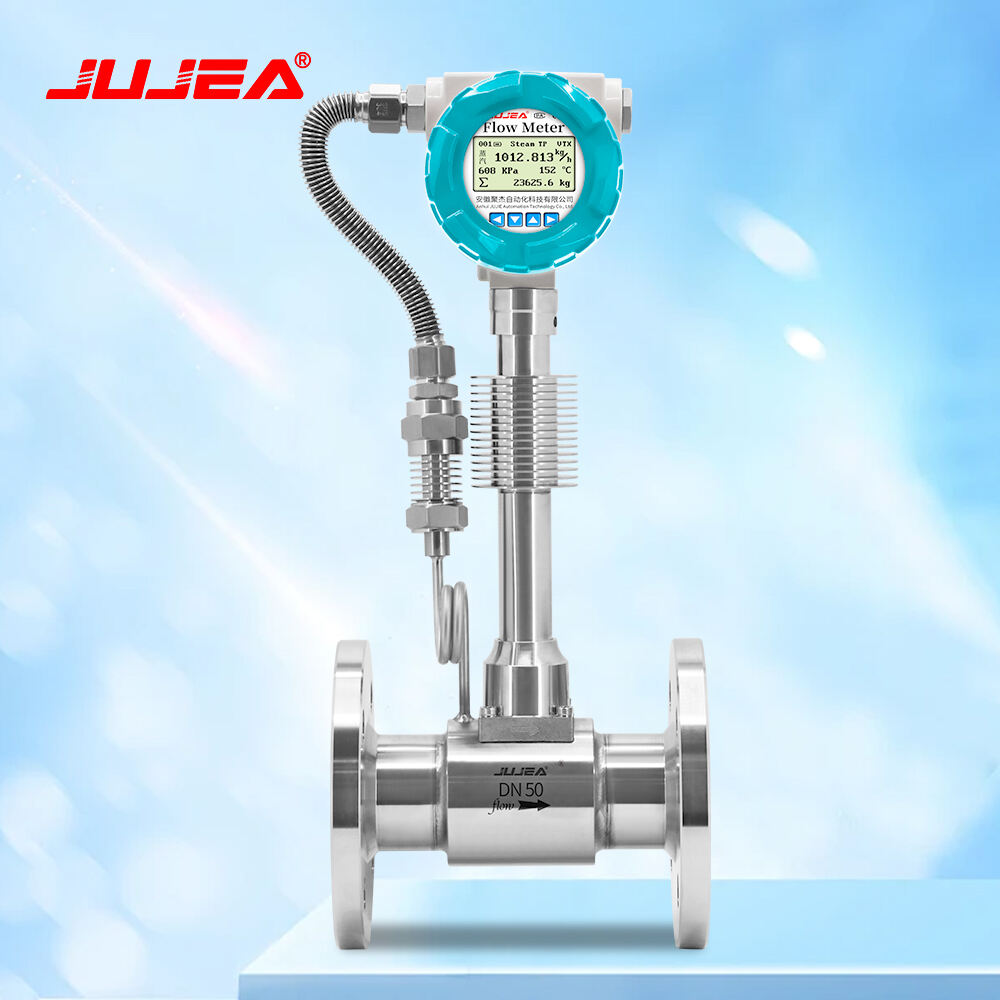

contor de debit termic

Un debitmetru termic este un dispozitiv avansat de măsurare care utilizează principiile transferului de căldură pentru a măsura cu precizie ratele de curgere ale gazelor în diverse aplicații industriale. Acest instrument sofisticat funcționează prin introducerea unei cantități precise de căldură în fluxul de mediu și măsurarea vitezei cu care această căldură se disipează, oferind astfel măsurători foarte exacte ale debitului. Debitmetrul este compus din doi senzori de temperatură, unul situat în amonte și celălalt în avalo, care lucrează împreună cu un element de încălzire. Pe măsură ce gazul trece prin debitmetru, acesta transportă căldura de la senzorul încălzit către senzorul din aval, creând o diferență de temperatură care este direct proporțională cu rata debitului masic. Această tehnologie este deosebit de eficientă pentru măsurarea aplicațiilor cu debite reduse și pentru gaze cu compoziții variabile. Debitmetrele termice se remarcă în medii care necesită măsurători precise ale ratelor de curgere a gazelor, cum ar fi monitorizarea emisiilor, sistemele de aer comprimat și urmărirea consumului de gaz natural. Capacitatea metrului de a măsura direct debitul masic, fără a necesita compensații suplimentare de presiune și temperatură, îl face un instrument valoros în procesele industriale moderne. Aceste debitmetre pot gestiona o gamă largă de dimensiuni ale conductelor și rate ale curgerii, oferind rapoarte excelente de reglare (turndown ratio) și menținând acuratețea chiar și în condiții dificile.