Versatile Application Range

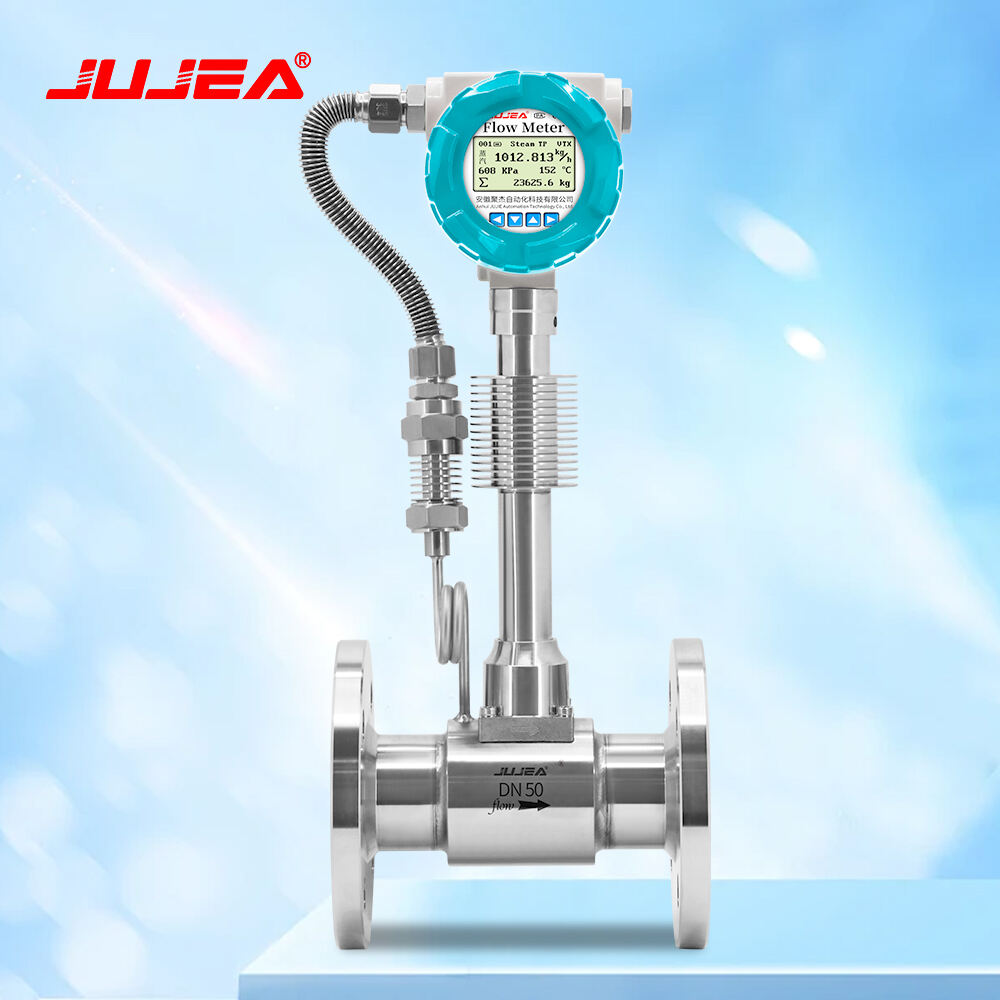

Turbine flow meters demonstrate remarkable versatility across various industrial applications. Their design allows them to handle multiple fluid types, from light hydrocarbons to water and industrial chemicals, making them suitable for diverse industries including oil and gas, chemical processing, and water treatment. The meters can be configured for different pipe sizes, from small-diameter laboratory applications to large industrial pipelines, with each size optimized for specific flow ranges. They perform effectively in both horizontal and vertical installations, providing flexibility in system design. The meters' ability to handle high flow rates while maintaining accuracy makes them ideal for custody transfer applications, while their fast response time suits them for batch processing operations. Their compatibility with various output signals, including pulse, analog, and digital communications, ensures easy integration with modern control systems and data acquisition equipment.