Jujea Flowmeter -Help you develop solutions for measuring flowmeters

Flowmeter: the core of key fluid measurement, ensuring safety, efficiency and energy saving in various industries

From agricultural irrigation, precision manufacturing to oil and gas transportation, flowmeters have become the "pulse monitor" of infrastructure, continuously measuring the "activity" of liquids and gases to ensure safe, reliable, energy-saving and efficient operation of the system. It provides not only instantaneous data, but also continuous and accurate flow visualization, providing key decision-making basis for enterprises to maintain stable operations and meet strict regulatory requirements.

1. Flowmeter: As an indispensable fluid "observer" in the industry

Definition: A flowmeter is a precision device used to measure the volume (or mass) of liquid or gas flowing through a pipe or channel in a specific time period.

By monitoring the flow rate in real time, the flowmeter allows the operator to clearly understand the material flow status inside the pipeline, pipe network and other systems. This is crucial because it can ensure the hydraulic balance of the system, ensure adequate supply at each node, identify abnormal flow rates (such as excessive flow rates may damage the pipeline), optimize process efficiency, save energy and reduce consumption, and comply with metering and billing and environmental protection regulations.

2. Water flow meter: Expert in measurement of water media

The water flow meter is a member of the flow meter family designed specifically for measuring water flow. It plays a key role in many scenarios:

Municipal water supply: Accurately measure drinking water consumption and metering in households and communities.

Sewage treatment: Monitor sewage flow, evaluate system processing capacity, prevent blockage, and comply with laws and regulations.

Industrial cooling: Track cooling water usage in factories, data centers and other places to ensure normal operation of equipment.

Agricultural irrigation: Accurately control irrigation water volume and improve water resource utilization.

3. Four major mainstream flow meters

Although the goal is the same - accurate flow measurement, the technical paths adopted by different flow meters are different.

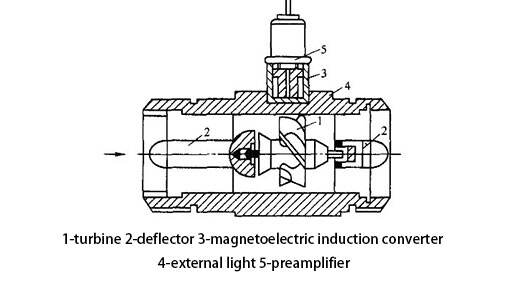

Mechanical (turbine) or propeller flow meter

Mechanical flow meters force the liquid to flow through a physical component that moves under the impetus of water flow. The most common mechanical flow meter uses a propeller to achieve this purpose. By measuring the rotation speed of the propeller or other mechanical parts, this flow meter can record the flow with high accuracy.

However, because the mechanical parts contained in this type of meter will wear out over time, mechanical flow meters require a relatively high degree of maintenance. Operators must replace bearings and ensure that the propeller remains properly aligned to obtain accurate readings.

However, mechanical flow meters require a relatively high degree of maintenance because these meters contain mechanical parts that wear out over time. Operators must replace bearings and ensure that the propeller remains properly aligned to obtain accurate readings.

Electromagnetic flowmeter (Magmeter)

Principle: Utilizes Faraday's law of electromagnetic induction. Electrodes establish a magnetic field on both sides of the pipe; the water flow cuts the magnetic lines of force to generate an induced voltage, the voltage value of which is proportional to the flow rate. No moving parts, very low maintenance cost; unobstructed measurement channel, no pressure loss; very high accuracy for conductive liquids (such as water); resistant to dirt. Electromagnetic flowmeters are only suitable for conductive liquids.

Principle: Ultrasonic signals are emitted into the fluid, and the flow velocity is calculated using the difference in propagation time of the upstream/reverse flow (time difference method) or the Doppler effect frequency shift (Doppler method).

Advantages: Non-contact measurement (clamp-on type), no pressure loss; suitable for large-diameter pipes; low maintenance requirements.

Limitations: Accuracy is affected by fluid properties (purity, bubbles, suspended matter) and pipe lining; installation requirements are high (straight pipe section, coupling agent); Doppler method requires fluid to contain scattering particles.

Vortex Flowmeter (Vortex)

Principle: Fluid flows through a bluff body (blunt body) to produce alternating vortices (Karman vortex street), and the vortex frequency is proportional to the flow rate. The flow rate is measured by detecting the frequency.

Advantages: No moving parts, sturdy structure, low maintenance requirements; suitable for liquids, gases, and steam.

Limitations: Accuracy decreases at low flow rates; sensitive to pipeline vibration; bluff bodies may produce a certain pressure loss; not suitable for low-viscosity fluids or media containing a large number of bubbles/solid particles.

IV. Why is accurate measurement so important?

Different companies and industries may have different requirements for flow meter accuracy. But generally speaking, the higher the accuracy of the flow meter, the greater its value to the company or organization.

The accuracy of flowmeters is no small matter. It directly affects operational efficiency, safety compliance and cost control:

Agriculture: Too much irrigation water will flood crops and cause them to rot, while too little irrigation water will cause drought and reduced production. Accurate flow control is the guarantee of a good harvest.

Wastewater treatment: Accurately measuring the flow of sewage and sludge is the key to preventing pipeline blockage, optimizing treatment processes and meeting emission standards.

Drinking water: Ensuring that each user point in a complex pipeline network can obtain stable and sufficient water pressure and water volume depends on accurate regional and user metering.

Industrial cooling: Insufficient cooling water flow causes equipment to overheat and shut down, while excessive flow wastes resources. Accurate control is the cornerstone of equipment safety and economic operation.

Industry: The precise proportioning and transportation of fluids such as water, steam, chemical raw materials, and process gases is the core link to ensure product quality and production efficiency.

Oil and gas: From wellhead to refinery to end user, accurate trade metering, leak detection and pipeline network balancing rely on high-performance flowmeters, even in the face of complex media and long-distance transportation.

V. How to choose your "best partner"?

Faced with a variety of flowmeter types, choosing the most suitable solution for an application requires comprehensive consideration of measurement requirements, installation and maintenance, and flowmeter life cycle:

In-depth understanding of your process:

Fluid type (water, oil, gas, steam, slurry?) and characteristics (viscosity, conductivity, cleanliness, solid content, temperature, pressure). Pipe size, material, installation direction. Flow range (minimum, common, maximum). Process conditions (continuous/intermittent, stable/pulsating?).

1. Clarify measurement requirements:

Accuracy level: Trade settlement? Process control? Only need to monitor trends?

Turndown: In what flow range does the instrument need to maintain accuracy?

Certification requirements: Is it required for custody transfer (such as OIML, API, MID, etc.) or specific industry certification?

2. Evaluate installation and maintenance:

Available straight pipe length: Affects the accuracy of some instruments (such as DP, Vortex, turbine).

Power supply and signal output: 4-20mA, pulse, HART, Modbus, field display required?

Accessibility and maintenance capability: Does the field environment allow for regular maintenance? What is the maintenance cost budget? Do you prefer a low-maintenance solution?

3. Consider life cycle costs: Not only the initial purchase price, but also the installation cost, long-term maintenance costs, energy consumption (pressure loss), instrument life, and potential downtime losses.

Flowmeter R&D engineer advice: A wise choice

Flowmeter technology is complex and the application scenarios vary widely. Working with an experienced flowmeter supplier or engineer

is a key step in avoiding risks and optimizing investments.

Jujea flowmeters can provide:

Professional selection guidance: Recommend the most suitable technology based on your specific working conditions.

Precise installation support: Ensure that the instrument performs at its best.

In-depth technical interpretation: Help understand the advantages and disadvantages of different solutions and their long-term impact.

Compliance consulting: Ensure that relevant standards and regulations are met.

Jujea China focuses on flow meter design, R&D, production, sales, and planning and customizing the most suitable flow meter products for you

Read this article about flow meter selection and 3 factors to consider when choosing a flow meter

No one knows flow meters better than the manufacturers and engineers who design, develop, manufacture and maintain flow meters. If you are not sure which flow meter is best for your project measurement, please contact jujea technology to become a partner. With decades of industry experience, experienced engineers or installation experts can help you understand installation requirements, maintenance costs, report accuracy, and other factors that are critical to the effective operation of flow meters.