vätskeflödesmätare

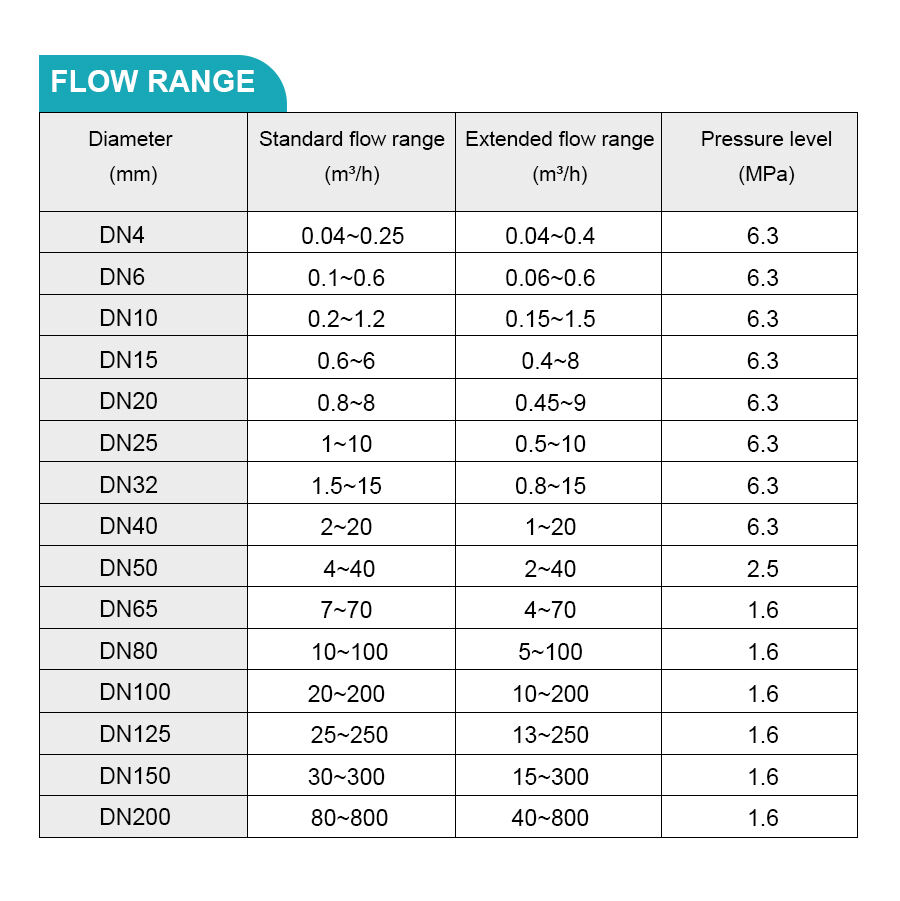

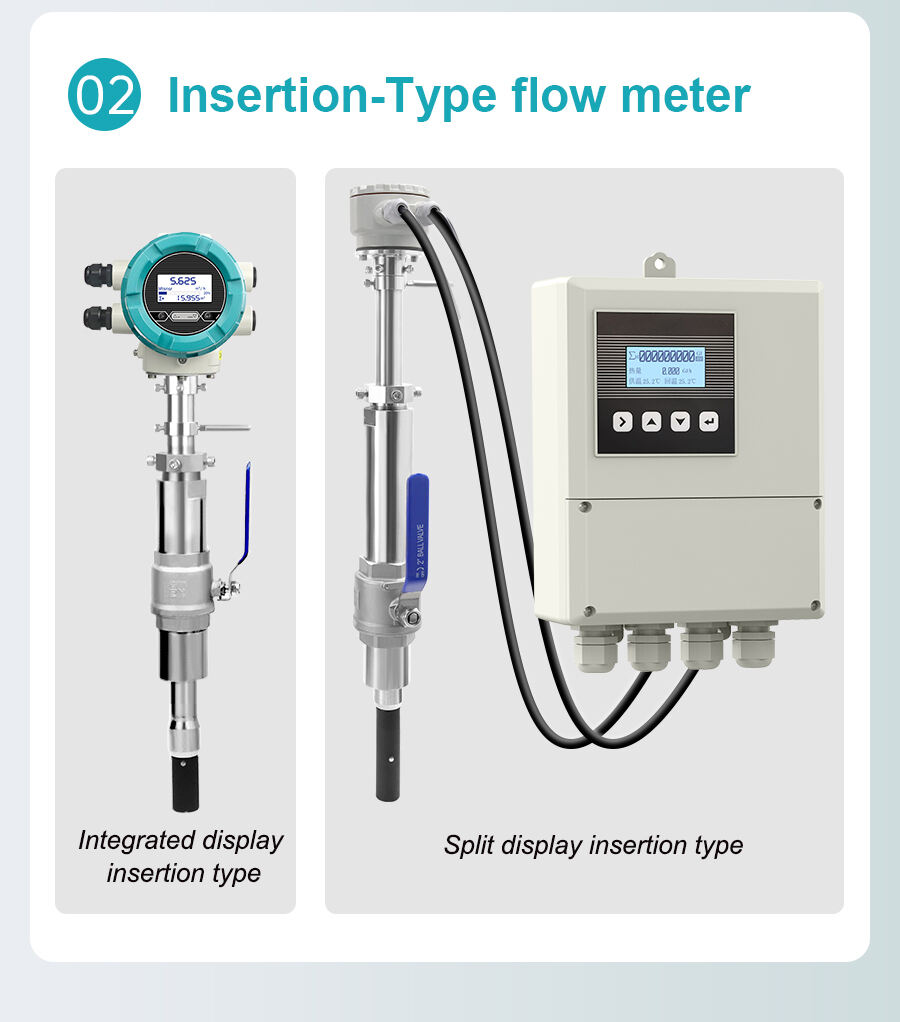

En flödesmätare är ett exakt instrument som är utformat för att mäta och övervaka volymen eller massan av vätska som rör sig genom en rörledning eller ett system. Denna väsentliga enhet kombinerar avancerad sensorteknik med robust teknik för att ge exakta mätningar över olika industriella tillämpningar. Mätaren använder flera mätprinciper, inklusive elektromagnetiska, ultraljuds- eller mekaniska metoder, för att upptäcka och kvantifiera vätskebevægelser. Moderna flödesmätare har digitala skärmar, datalagringsmöjligheter och fjärrövervakningsmöjligheter, vilket gör dem ovärderliga i processstyrnings- och automatiseringssystem. Dessa enheter är avgörande inom industrier som vattenbehandling, kemisk bearbetning, produktion av livsmedel och drycker och läkemedelstillverkning. De kan hantera olika typer av vätskor, från vatten till frätande kemikalier, och de fungerar under olika tryck- och temperaturförhållanden. Teknologin innehåller avancerade kalibreringssystem och självdiagnosfunktioner för att bibehålla noggrannhet och tillförlitlighet under längre perioder. Många modeller innehåller även inbyggda temperaturkompensations- och tryckkorrigeringsmekanismer för att säkerställa exakta mätningar oavsett miljöförhållanden. Deras modulära konstruktion gör det enkelt att installera, underhålla och integrera med befintliga styrsystem, medan deras robusta konstruktion garanterar lång livslängd i krävande industriella miljöer.