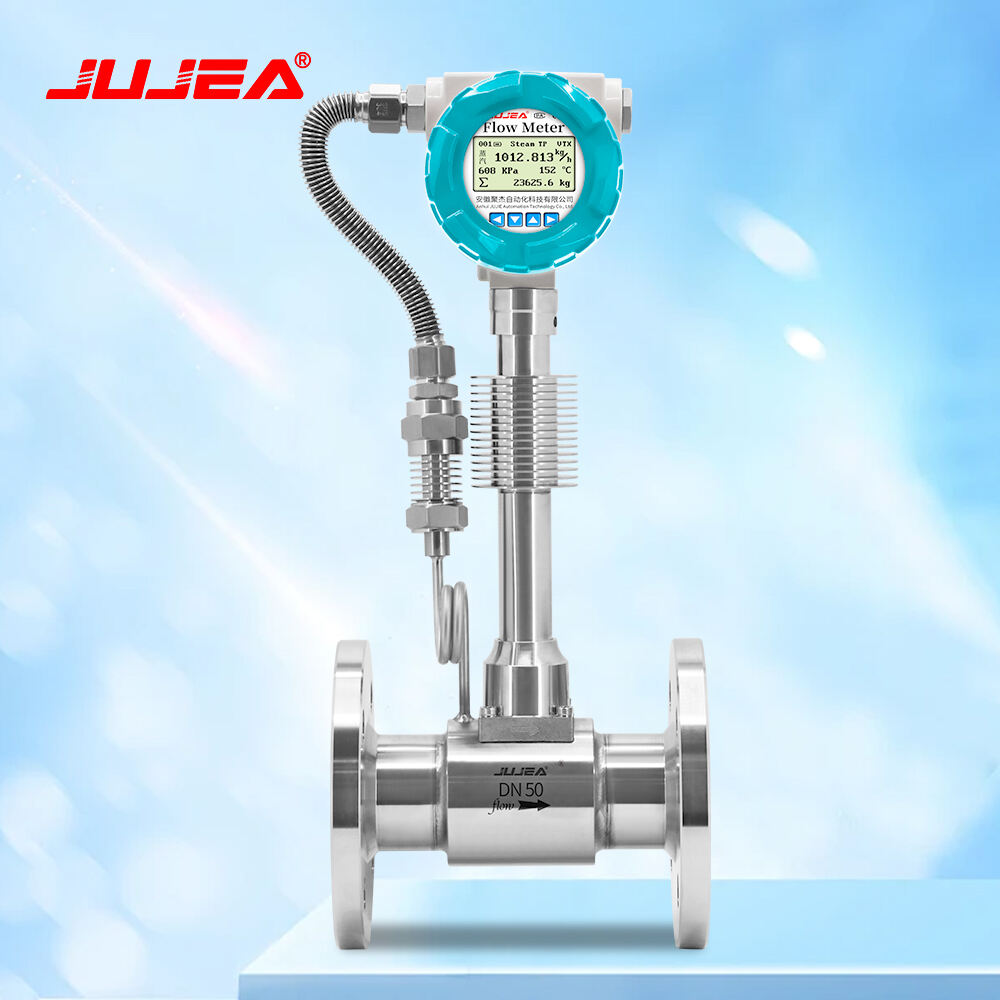

flow meter transducer

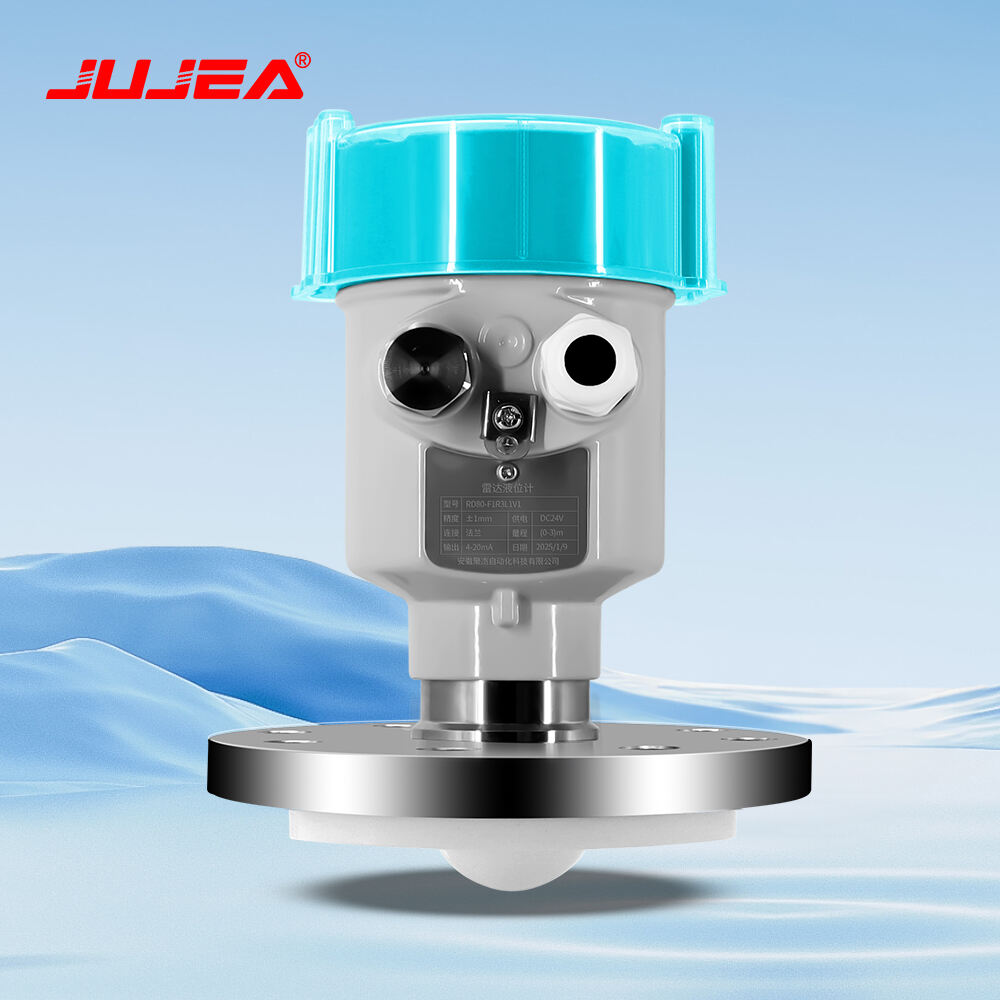

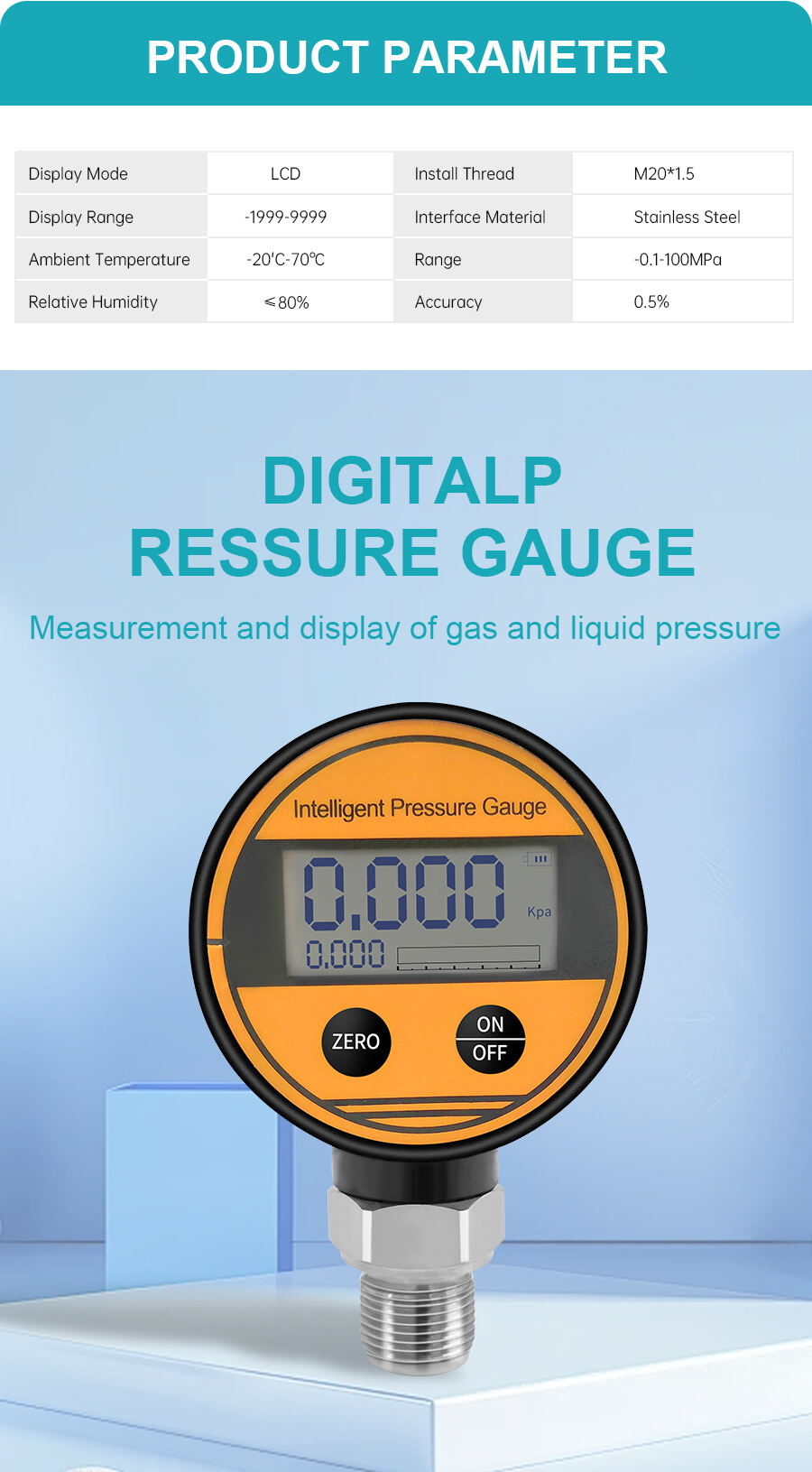

A flow meter transducer is a sophisticated measurement device that converts fluid flow rates into electrical signals for precise monitoring and control purposes. This essential instrument combines advanced sensing technology with reliable measurement capabilities to provide accurate flow data in real-time. The device operates by utilizing various physical principles, such as electromagnetic induction, ultrasonic waves, or mechanical displacement, to detect and measure fluid movement through a system. Flow meter transducers play a crucial role in numerous industries, including manufacturing, chemical processing, water treatment, and energy production. The device's ability to maintain accuracy across different flow conditions and its robust construction make it invaluable for both liquid and gas flow measurements. Modern flow meter transducers feature digital outputs, temperature compensation, and self-diagnostic capabilities, ensuring reliable performance in demanding industrial environments. These instruments can measure flow rates ranging from microscopic amounts to massive industrial volumes, adapting to various pipe sizes and fluid types. The integration capabilities of flow meter transducers with modern control systems enable automated process control, data logging, and remote monitoring, making them essential components in smart manufacturing and Industry 4.0 applications.