flow sensor ultrasonic

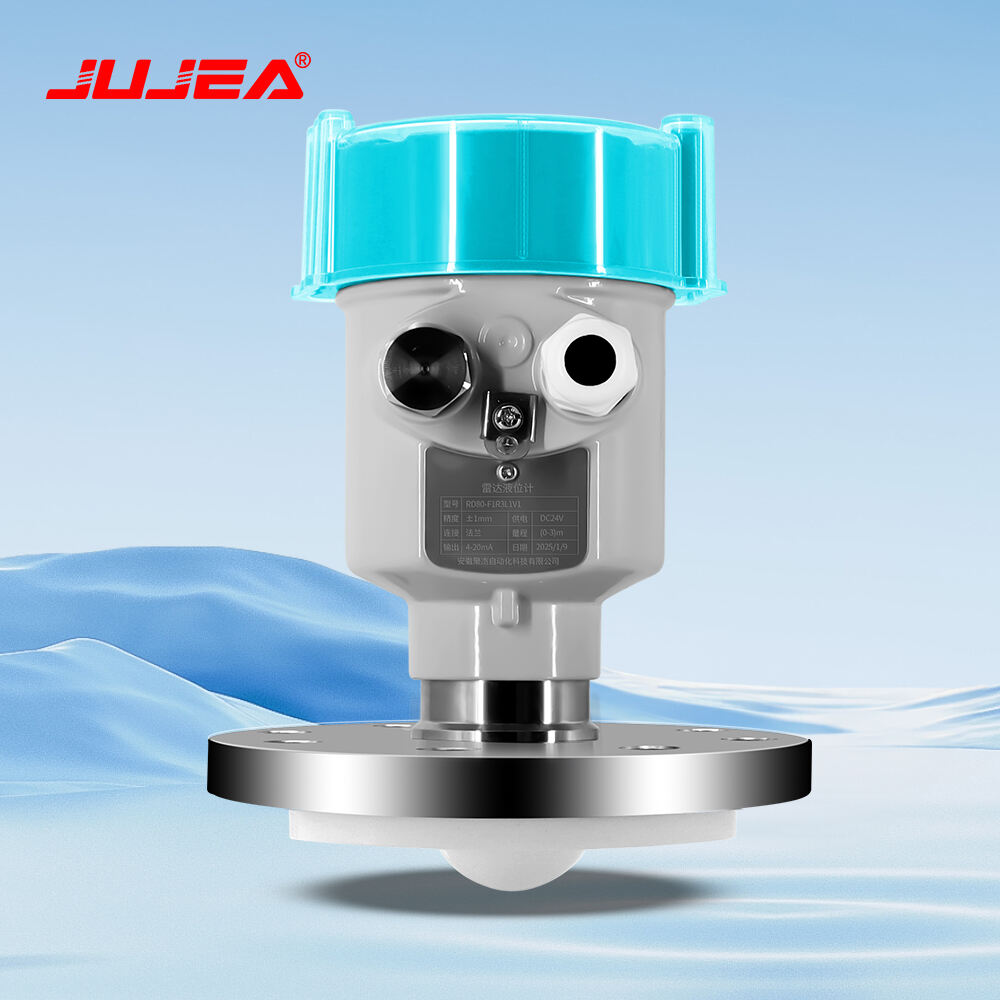

Flow sensor ultrasonic technology represents a cutting-edge solution in fluid measurement and monitoring systems. These advanced devices utilize ultrasonic waves to accurately measure liquid flow rates without direct contact with the medium, ensuring non-invasive and precise measurements. The technology works by sending ultrasonic pulses between transducers, measuring the time difference in signal transmission with and against the flow direction. This sophisticated measurement principle enables the device to calculate flow rates with remarkable accuracy. Flow sensor ultrasonics are designed with dual-path configurations, allowing for redundant measurements and enhanced reliability. They operate effectively across a wide range of pipe sizes, from small-diameter domestic applications to large industrial installations. The sensors can handle various liquid types, including water, chemicals, and oil-based fluids, making them versatile for multiple industries. These devices typically feature digital displays for real-time monitoring and can be integrated with modern control systems through standard communication protocols. Their non-intrusive nature prevents pressure drops in the system and eliminates the need for regular maintenance associated with mechanical flow meters. The technology also includes advanced signal processing capabilities to filter out noise and ensure accurate readings even in challenging environmental conditions.