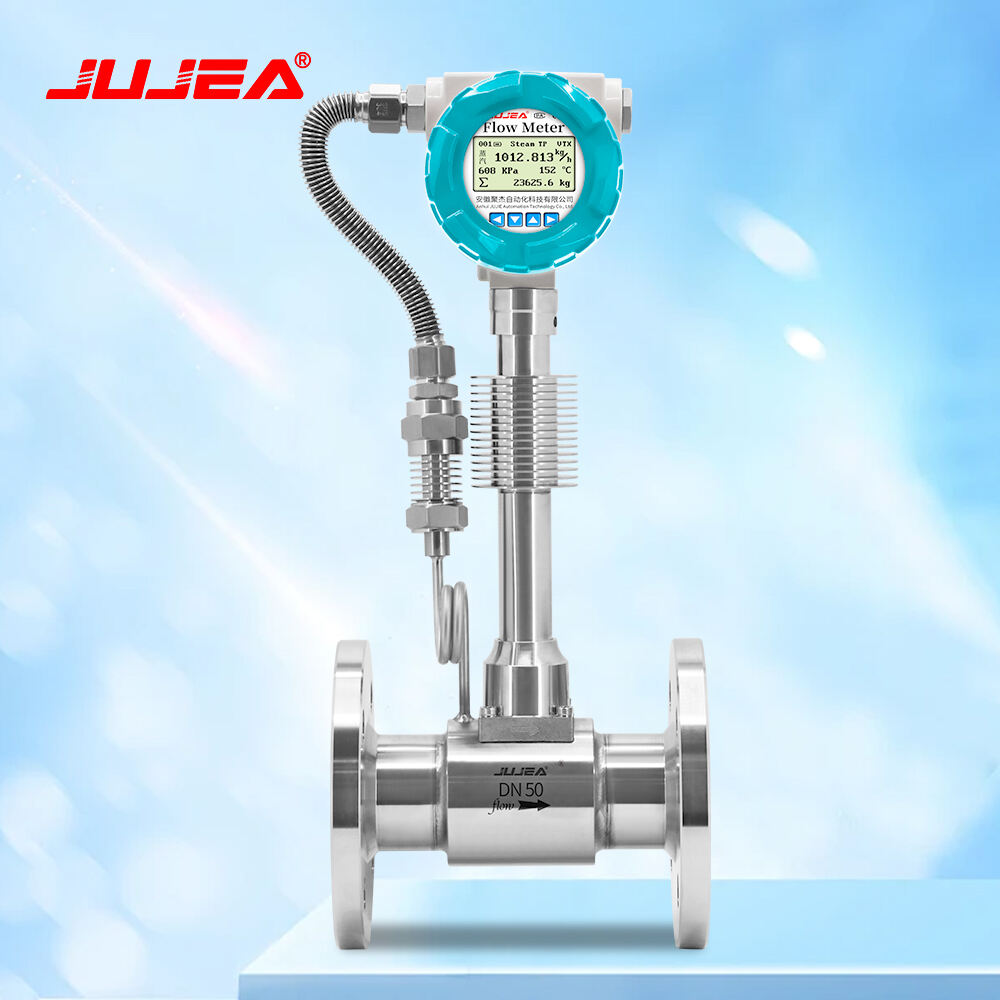

hydrogen flow meter

A hydrogen flow meter is a sophisticated measuring instrument designed to accurately quantify the flow rate of hydrogen gas in various industrial and research applications. This precision instrument utilizes advanced sensing technologies to measure and monitor hydrogen flow with exceptional accuracy, making it essential for processes involving hydrogen fuel cells, chemical manufacturing, and energy applications. The device incorporates specialized materials and design features to ensure safe operation when handling hydrogen, which is known for its unique properties and potential safety considerations. Modern hydrogen flow meters often integrate digital displays and smart connectivity options, allowing for real-time monitoring and data logging capabilities. These meters employ various measurement principles, including thermal mass flow, Coriolis effect, and differential pressure methods, each optimized for specific flow ranges and application requirements. The technology behind these meters has evolved to address the growing demands of the hydrogen economy, particularly in renewable energy applications and industrial processes. They are engineered to maintain accuracy across wide flow ranges and operating conditions, with built-in temperature and pressure compensation features to ensure reliable measurements regardless of environmental variations. The meters also incorporate safety features such as leak detection and automatic shutoff mechanisms, making them suitable for both laboratory and industrial environments.