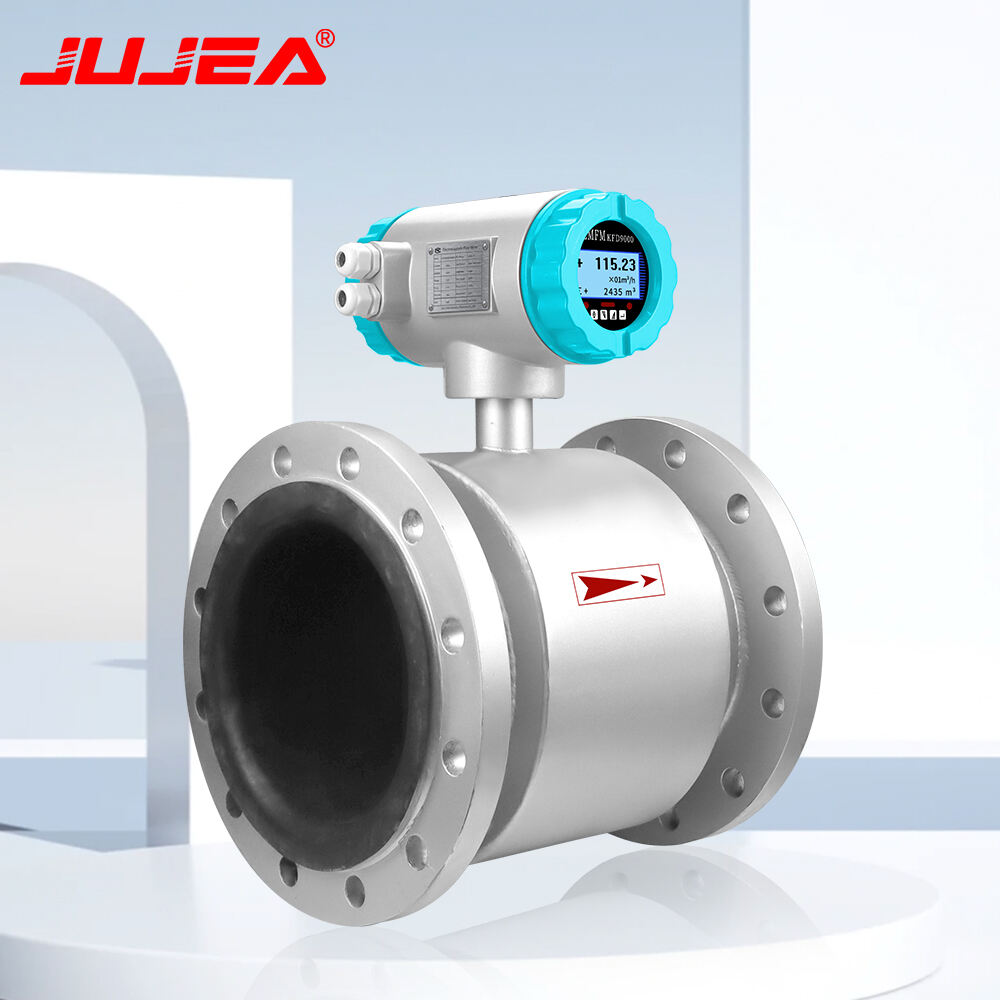

magnetic flow sensor

A magnetic flow sensor, also known as an electromagnetic flowmeter, represents a sophisticated measurement device that operates on Faraday's law of electromagnetic induction to accurately measure the flow rate of conductive liquids. This innovative technology consists of two main components: magnetic coils that generate a magnetic field and electrodes that detect the induced voltage. When a conductive fluid passes through the sensor's measurement tube, it creates a voltage proportional to the flow velocity. The device offers exceptional accuracy across a wide range of applications, maintaining consistent performance even with varying fluid properties. Modern magnetic flow sensors incorporate advanced signal processing capabilities, enabling them to filter out noise and provide stable readings in challenging industrial environments. These sensors excel in measuring flow rates in industries such as water treatment, chemical processing, food and beverage production, and pharmaceutical manufacturing. They operate without any moving parts, which significantly reduces maintenance requirements and extends operational life. The sensor's design allows for bi-directional flow measurement and can handle both clean and particulate-laden fluids without compromising accuracy. Additionally, these devices can be integrated with various control systems through standard communication protocols, making them ideal for automated process control applications.