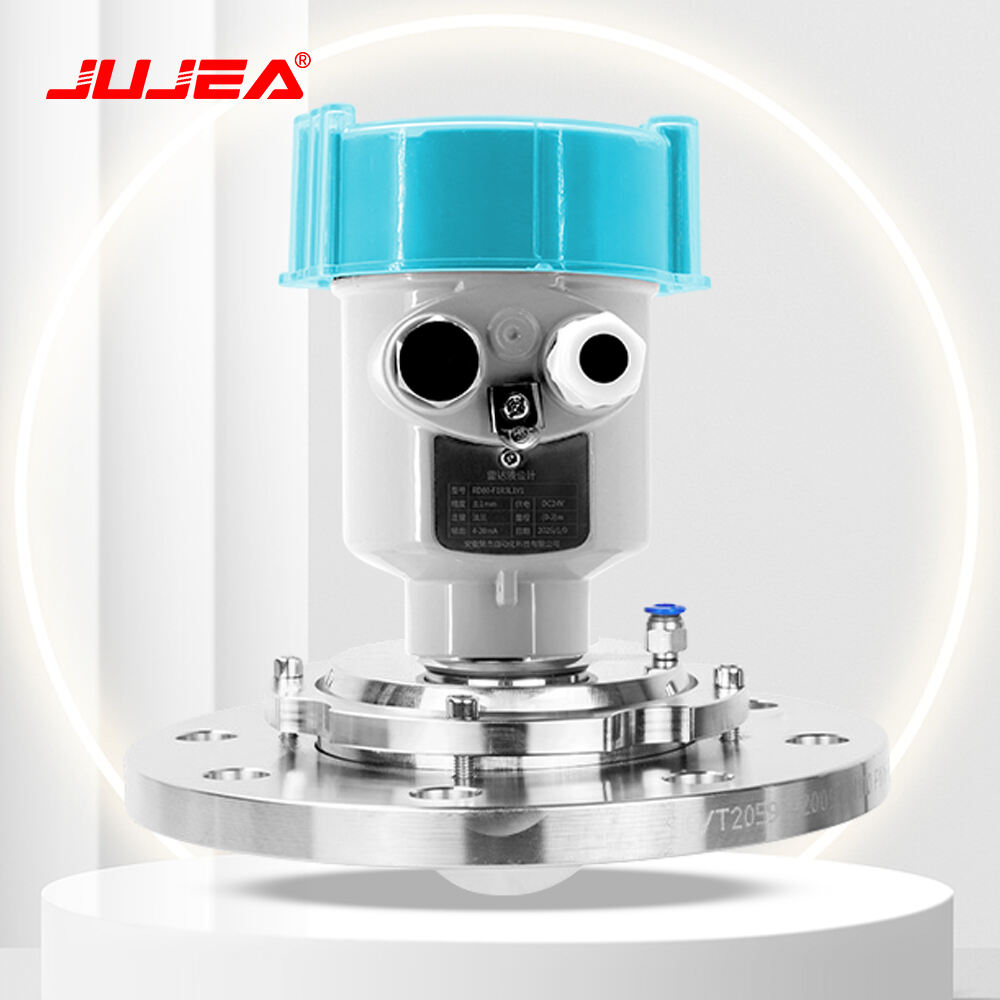

non contact water level sensor

Non contact water level sensors represent a cutting-edge solution for monitoring liquid levels without physical contact with the measured medium. These sophisticated devices utilize various technologies such as ultrasonic waves, radar, or optical sensors to accurately determine water levels in tanks, reservoirs, and other containers. The sensor emits signals that bounce off the liquid surface and return to the detector, calculating the distance based on the time taken for the signal to return. This advanced measurement technique ensures precise readings while maintaining the integrity of both the sensor and the liquid being measured. These sensors can operate in diverse environments, from industrial processing plants to municipal water management systems, offering real-time monitoring capabilities with exceptional accuracy. The technology incorporates smart features such as automatic temperature compensation and digital signal processing to ensure reliable measurements regardless of environmental conditions. With their ability to interface with modern control systems through various communication protocols, these sensors enable automated monitoring and control of liquid levels, making them essential components in modern water management systems. The durability and longevity of non contact water level sensors are enhanced by their non-invasive measurement approach, which eliminates wear and tear associated with traditional contact-based methods.