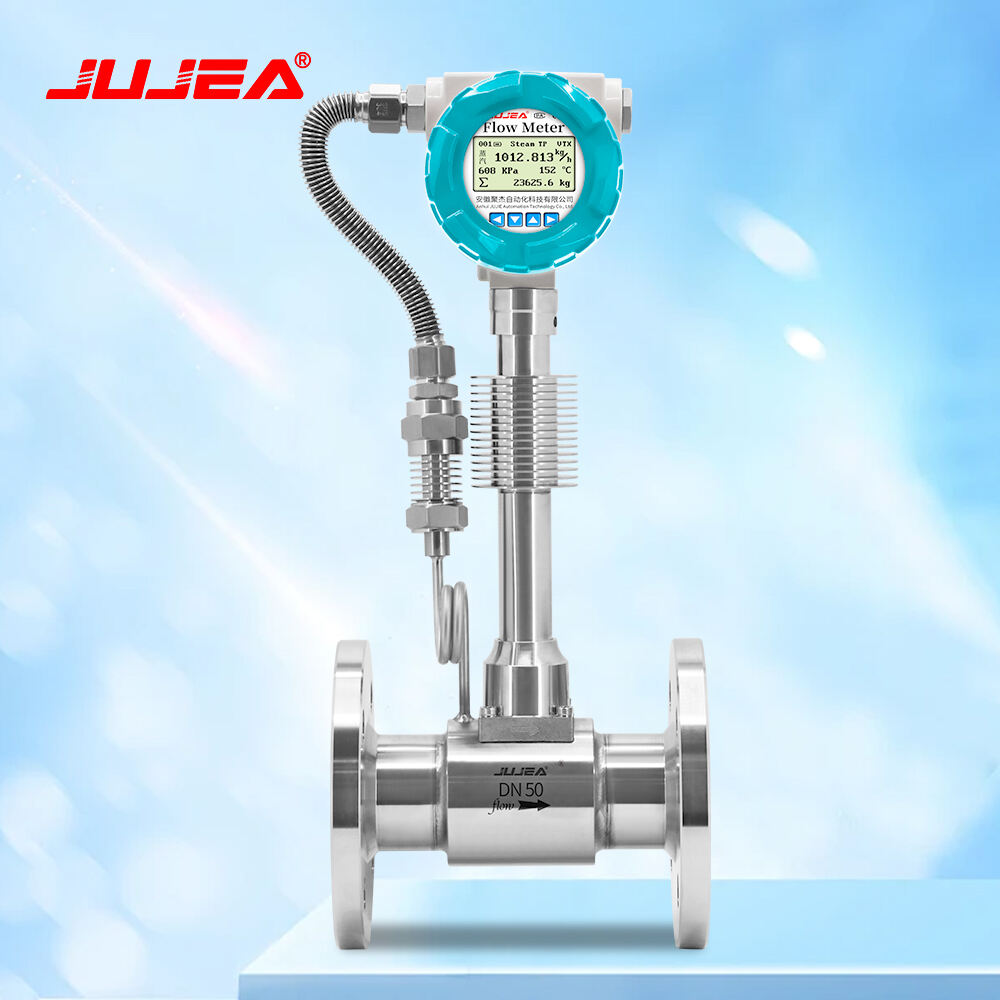

fuel flow sensor

A fuel flow sensor is a sophisticated measuring device that plays a crucial role in monitoring and optimizing fuel consumption in various applications. This precision instrument accurately measures the rate at which fuel flows through a system, providing real-time data essential for efficient operation and maintenance. The sensor employs advanced technology to detect and measure fuel movement using various methods, including positive displacement, turbine, or ultrasonic measurement techniques. These sensors are designed to operate across a wide range of temperatures and pressures, ensuring reliable performance in demanding environments. The device typically consists of a flow detection element, signal processing electronics, and output interface, working together to deliver precise measurements. In automotive applications, fuel flow sensors help optimize engine performance and fuel efficiency by providing accurate data to the engine control unit. In industrial settings, these sensors are vital for monitoring fuel consumption in generators, heating systems, and large machinery. The technology also finds extensive use in aviation, where precise fuel management is critical for flight safety and operational efficiency. Modern fuel flow sensors often incorporate digital interfaces and advanced diagnostics, enabling integration with broader monitoring and control systems while facilitating preventive maintenance through early detection of fuel system anomalies.