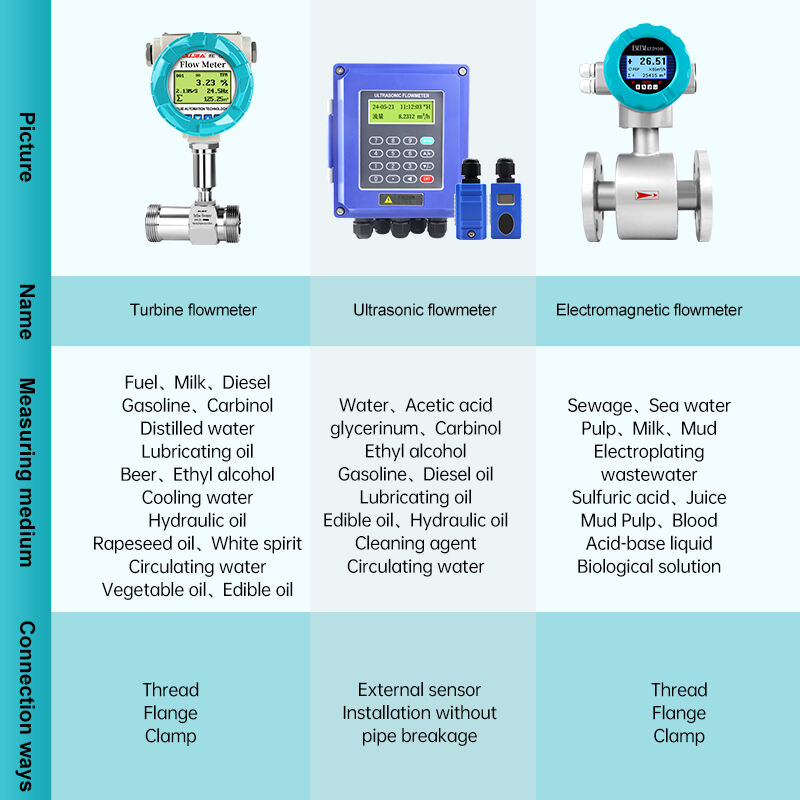

Liquid & Milk & Water Flow Meters丨 Turbine &Ultrasonic &Electromagnetic Flow meter manufacturers

Flowmeters for measuring liquids are available with customizable configurations.

Turbine flowmeters: Suitable for low-viscosity liquids such as water, oil, and solvents, they are widely used for pipeline metering in the petroleum, chemical, and pharmaceutical industries.

Ultrasonic flowmeters: Non-contact, suitable for water, sewage, acids, and alkalis, they excel in municipal water supply, environmental monitoring, and industrial circulating water systems.

Electromagnetic flowmeters: Suitable for measuring conductive liquids such as impure sewage and slurries, they offer stable performance in highly corrosive environments found in chemical and metallurgical industries.

Description

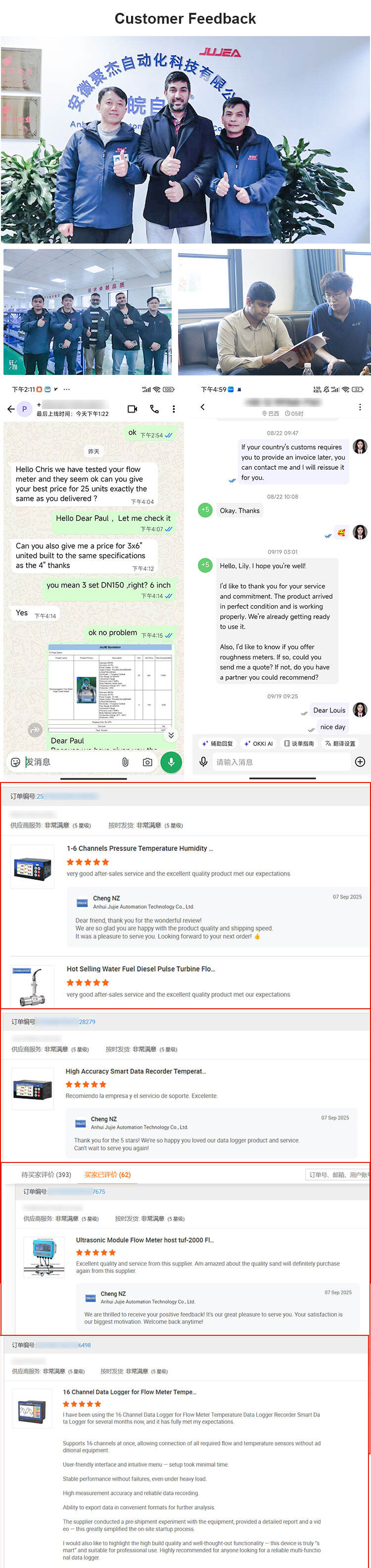

JUJEA is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in providing reliable liquid and gas flow measurement and control solutions for environmental protection, industrial water treatment, chemicals, petroleum, metallurgy, pharmaceuticals, food and beverages, medical gases, and industrial gases. With over 15 years of experience in flow instrumentation manufacturing, we can help you build effective solutions for flow measurement, control, and data logging.

JUJEA's factory is located in Wuhu, Anhui Province. Our main products include ultrasonic flowmeters, electromagnetic flowmeters, turbine flowmeters, gas flowmeters, level gauges, integrators, temperature and pressure instruments, and recorders.

We have successfully implemented over 50,000 solutions worldwide.

We hold hundreds of patents and certifications, and boast a leading R&D team, a wide range of high-precision machining equipment, advanced calibration equipment, and a quality inspection team to ensure product quality.

The company has obtained ISO9001:2015 quality management certification, and our products have obtained the EU CE mark.

Today, with the joint efforts of all JUJEA people, our products have covered more than 30 provinces, municipalities and autonomous regions in China, and exported to the United States, Russia, Germany, Spain, Malaysia, Thailand, Brazil, Argentina and other nearly 100 countries and regions, winning a good reputation and credibility.

| PARAMETERS OF TURBINE FLOWMETER | |

| Parameter | Configuration |

| Medium | No impurities, low viscosity, no strong corrosive liquid |

| Diameter (mm) | DN4~DN200 |

| Precision | 0.5%; 1.0% |

| Medium temperature | -20~+80℃; -40~180℃ optional |

| Pressure level | 1.6MPa、2.5MPa、6.3MPa、42MPa |

| Viscosity of medium | <5×10⁻⁶m²/S(For liquids with a viscosity greater than 5×10⁻⁶m²/S, the sensor is carried out) |

| Power supply | DC12V;DC24V; 3.6V lithium battery |

| Output signal | Pulse、4-20mA、RS485、0-5V、0-10V |

| Environmental | -20℃ ~ +50℃; 5%RH ~ 95%RHs |

| Explosion-proof grade | Exd IIC T6 Gb |

| Valve body material | SS304(316L) , PE、PTFE |

| Impeller material | 2Cr13; BearingYs8 Alloy; Guide: SS304(316); |

| Connection method | Internal/external threads, flanges, clamps |

| Protection grade | IP65、IP68 |

| PARAMETERS OF ELECTROMAGNETIC FLOWMETER | |

| Parameter | Configuration |

| Nominal Diameter | Pipe PTEE lining:DN10-DN500;Pipe Rubber lining:DN65-DN1200 |

| Precision level | 0.5 |

| Repeatability error | Measured value ±0.1% |

| Medium Temperature | Conventional rubber lining:-20°~+70℃;PTEE lining:-20°~+120℃ |

| Rated working pressure | 0.6 Mpa; 1.0Mpa; 1.6Mpa;4.0Mpa |

| Velocity range | 0.5~5m/s |

| Conductivity range | ≥20us/cm |

| Signal output | 4-20mA,Pulse,RS485,Hart |

| Power supply | AC220V; DC24V; Battery |

| Installation requirements for straightpipe segments | upstream ≥10DN;downstream ≥25DN |

| Connection type | Flange; Thread; Tr-clamp |

| Protection Level | IP65 (IP68 can be customized) |

| Environment temperature | -25℃~+60℃ |

| Power consumption | ≤20W |

| PARAMETERS OF ULTRASONIC FLOWMETER | |

| Parameter | Configuration |

| Measurement accuracy | Level 1.5 |

| Repeatability | 0.20% |

| Flow rate range | Below DN200 (inclusive)0.3-4m/s; above DN200 0.3-6m/s |

| Measurement principle | Principle of ultrasonic propagation time difference, dual CPUs working in parallel, 4-byte floating point operation |

| Measurement period | 500mS (2 times per second) |

| Working power supply | Isolated DC8-36V or AC85-264V |

| Signal input | 3 channels of 4-20mA analog input, which can input pressure, liquid level temperature and other signals, 2 channels of three-wire platinum resistors |

| Signal output | 1 isolated Rs485 output, 1 isolated 4-20mA or 0-20mA output (active or passive optional); Optional HART protocol; dual isolated OCT outputs; 1 bidirectional serial interface, universal interface for peripherals connects 4-20mA, frequency signals, thermal printers, data loggers, etc. |

| Power dissipation | Working current 50mA (when the keyboard is not connected and the buzzer does not sound) |

| Display | 2X 10 Chinese character backlight display (Chinese and English bilingual optional) |

| Operate | 16-button or 4-button window operation |

| Other functions | Automatically memorizes the previous 512 days, the previous 128 months and the previous 10 years. The positive and negative net accumulated flow rates can be automatically remembered for the previous 30 times. The power-on and power-off times and flow rates can be automatically or manually added, and can be read out through the Modbus protocol. |

| Sensor | External application, insertion and tube type |