Problems faced by customers

In Argentina's industrial production scenarios, customers simultaneously face the dual challenges of fuel storage tank level monitoring and grain silo (soybean, corn) level measurement.

For fuel storage tanks, traditional liquid level measurement methods (such as float type, hydrostatic type, etc.) have many limitations: the float type is easily affected by the viscosity of the medium and prone to jamming after long-term use; the hydrostatic type is interfered with by changes in the medium density, and it is difficult to install and maintain under a 15-meter measuring range.

In the measurement of grain silo level, the challenges are even more prominent: on the one hand, the maximum height of grain silos can reach 30 meters, making it difficult for conventional measuring equipment to cover such a large range; on the other hand, a large amount of dust is generated during the storage of soybeans and corn, and this dust easily adheres to the surface of the measuring probe, causing the measurement accuracy of ordinary level gauges to drop sharply or even completely fail, seriously affecting the customer's precise control of inventory, and thus interfering with the efficiency of production scheduling and inventory management.

Core Customer Requirements

2.1 Fuel Storage Tank Measurement Requirements

Measurement object: Fuel

Range requirement: Compatible with 15-meter-high fuel storage tanks

Communication Requirements: Must have RS485 communication output to facilitate connection to the customer's existing automated control system, enabling data transmission and centralized management.

Accuracy requirement: industrial-grade measurement accuracy to ensure accurate and reliable fuel inventory data

2.2 Grain Silo Level Measurement Requirements

Measurement objects: grains such as soybeans and corn

Range requirement: Cover a maximum grain silo height of 30 meters

Communication requirements: RS485 communication output is also required to achieve automated collection of material level data.

Special requirement: Due to the issue of dust adhesion in grain silos, a purging function needs to be equipped to prevent dust from adhering to the probe and ensure the long-term stability and accuracy of measurements.

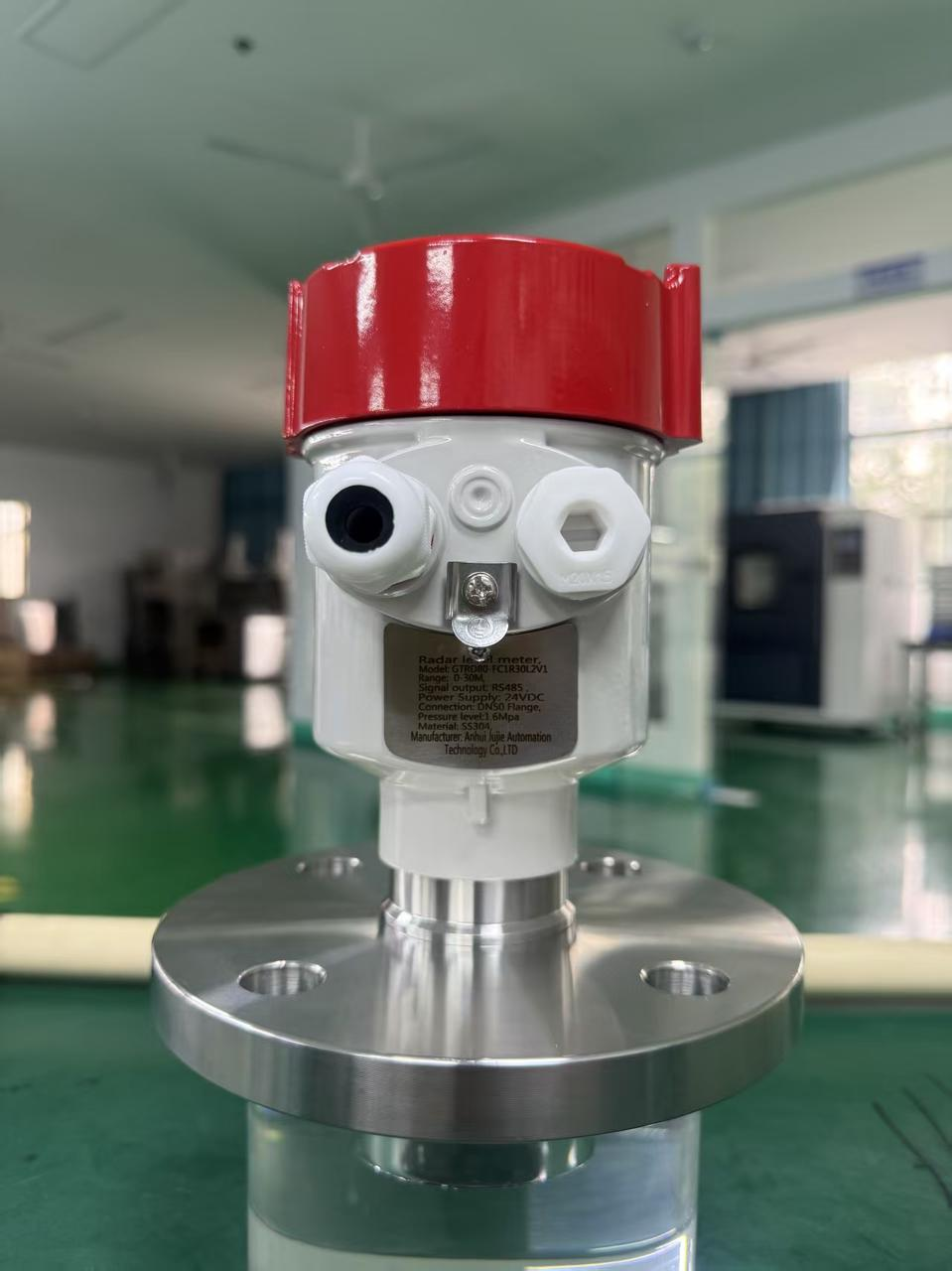

Solution: Customized configuration of the Jujea brand 80G radar level gauge

In response to the customer's dual-scenario requirements, Chinese

manufacturer Jujea has provided two customized 80G radar level gauges, with the specific configurations as follows:

| Application scenarios |

Product Model |

range |

accuracy |

Connection method |

power supply |

Signal output |

Special features |

| fuel tank level |

80G Radar Level Gauge |

0-15M |

±1mm |

304 flange (DN50) |

DC24V |

RS485 (4-wire) |

Standard industrial-grade configuration |

| Grain silo level |

80G Radar Level Gauge |

0-30M |

±1mm |

304 flange (DN50) |

DC24V |

RS485 (4-wire) |

Universal flange with purging function |

Analysis of Product Technical Advantages

3.180G Radar Technology Core Advantages

High precision: Both

products achieve a measurement accuracy of ±1mm, far higher than traditional liquid level / material level measurement devices, ensuring data accuracy.

Small installation blind zone: The inherent technical advantages of 80G radar enable it to maintain effective measurement even in the area near the tank bottom/bin bottom, avoiding the "large blind zone" defect of traditional equipment and achieving full-range, blind-spot-free measurement.

Wide range coverage: It covers the range requirements of 0-15M (fuel tank) and 0-30M (grain silo) respectively, meeting the measurement range requirements of customers in different scenarios.

3.2 Targeted Functional Design

For fuel storage tank scenarios, conventional 304 flanges (DN50) are used for connection, which are compatible with industrial pipeline standards, easy to install, corrosion-resistant, and adaptable to the medium characteristics of fuel.

For the grain silo scenario, configuring a universal flange with a purging function can initiate purging periodically or based on the dust adhesion situation to remove dust from the probe surface, fundamentally solving the problem of dust interfering with measurement and ensuring long-term stable operation.

3.3 Compatibility of Communication and Power Supply Both products use DC24V power supply and RS485 (4-wire) signal output, perfectly adapting to the power supply and communication protocols of the customer's existing automation system. They can achieve seamless data connection without additional modification, reducing the cost of system integration.

Implementation Results

After adopting the solution with the Jujea brand 80G radar level gauge, the customer achieved the following significant results:

4.1 Measurement accuracy and stability have been significantly improved.

The level measurement error of fuel storage tanks is controlled within ±1mm, and the accuracy of inventory data has achieved a qualitative leap, providing a reliable basis for the management of fuel purchase, sale, and storage.

In grain silo level measurement, radar level gauges with purging function effectively resist dust interference, maintaining stable measurement accuracy even in high-dust environments and completely resolving the previous measurement failure issues caused by dust.

4.2 Operational Efficiency and Cost Optimization

Automated data acquisition has replaced manual inspections, saving a significant amount of labor costs. Meanwhile, the real-time nature of the data enables customers to conduct production scheduling and inventory management more efficiently.

The high reliability of the equipment reduces maintenance frequency and failure losses, resulting in a significant decrease in long-term operating costs.

4.3 Overall Solution Cost is Clear and Controllable. This solution, on the premise of meeting all the client's functional and performance requirements, has achieved a high-cost-effective input-output ratio.

In summary, the Jujea brand 80G radar level gauge, with its accurate measurement performance, targeted functional design, and good compatibility, has successfully solved the dual challenges faced by Argentine customers in fuel and grain level measurement, providing strong technical support for the efficient operation of their industrial production.