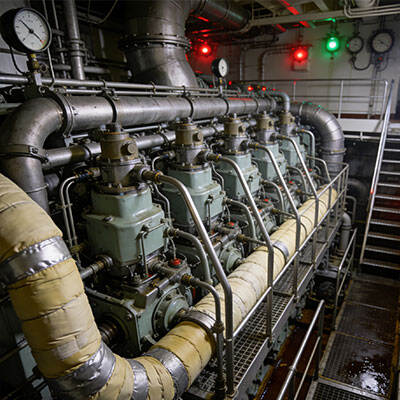

In the operation and maintenance of cruise ship power systems, the flow difference between the pipelines before and after the engine is one of the core data points for evaluating equipment conditions and preventing faults. A French cruise ship operator once faced the pain point of "being unable to monitor the flow difference between the engine inlet and outlet in real time". Finally, through the customized solution of China - Anhui JUJEA Automation Technology Co., Ltd., it achieved accurate data collection and intelligent analysis.

I. Core Customer Issues: The "Data Blind Spot" in Power System Conditions

As a local French cruise ship operator, the customer’s core demand focused on monitoring the operating status of cruise ship engines — the stability of its power system is directly related to navigation safety and energy consumption costs. In actual operations, the customer faced three key problems:

Data Gaps: Flow data from the engine’s inlet and outlet pipelines could only be collected separately; the "flow difference" could not be obtained in real time, making it difficult to identify potential faults such as pipeline blockages or equipment wear;

Low Efficiency: The traditional manual method of recording flow data was time-consuming and labor-intensive, and also suffered from data lag and large errors, which could not support real-time decision-making;

Functional Limitations: Existing monitoring equipment lacked the integrated functions of "flow accumulation + difference calculation", requiring additional devices to be configured, which increased operation and maintenance costs and system complexity.

II. Requirements and Challenges: Precise Monitoring Needs Under High Working Conditions

The customer’s specific requirements were clear: install one flow meter each in the engine’s inlet and outlet pipelines, collect flow data in real time via a data logger, automatically calculate the difference between the two, and simultaneously implement the flow accumulation function.However, the cruise ship’s operating environment posed multiple challenges for the solution’s implementation:

Harsh Working Conditions: The medium flow rate in the cruise ship’s engine pipeline fluctuates greatly, and the pressure is high (up to 6.3MPa), placing extremely high demands on the flow meter’s pressure resistance and anti-interference capabilities;

Data Accuracy: The calculation error of the flow difference must be controlled within a very small range, otherwise it will affect the accuracy of fault judgment;

Integration Requirements: The equipment must be compatible with the entire process of "data collection - difference calculation - data storage", and the operation interface must support English display (to match the usage habits of the French operation and maintenance team).

III. Customized Solution by China - Anhui JUJEA Manufacturer

In response to the customer’s needs and scenario characteristics, China - Anhui JUJEA Automation Technology Co., Ltd. provided an integrated solution of "turbine flow meter + intelligent data logger", with the core logic of "two-point collection + real-time calculation + data storage".

Product Configuration: Hardware Combination Adapted to High Working Conditions

The two products selected in the solution were parameter-matched to the characteristics of the cruise ship power system:

Turbine Flow Meter (4 units)Model parameters: Diameter DN15, flow range 0.6~6m³/h, accuracy ±1%, connection method male thread, body material 304 stainless steel, impeller material 2Cr13, pressure rating 6.3MPa, power supply 24VDC, signal output 4-20mA.Adaptability: The pressure-resistant, corrosion-resistant material and precise signal output fully match the medium and pressure environment of the engine pipeline.

Data Logger GT68R (2 units)Functional parameters: 3-channel design (2 channels of 4-20mA signal input + 1 channel for difference calculation), supports flow accumulation function, equipped with 2 channels of relay output, RS485 communication interface and free PC software, power supply 24VDC, interface in English version.Adaptability: Realizes the flow difference calculation of "Channel 1 (inlet flow) - Channel 2 (outlet flow)" via program formulas, while integrating data storage and communication functions to meet the customer’s needs for "real-time difference + data traceability".

Solution Logic: Full Process Coverage from Collection to Analysis

The specific implementation process is:

Install 1 turbine flow meter each in the cruise ship engine’s inlet and outlet pipelines (2 in total; 4 are configured in the solution as redundant backups); Connect the 4-20mA signals of the two flow meters to the first and second channels of the data logger GT68R respectively;

Use the logger’s built-in program to automatically calculate the difference between "Channel 1 (inlet flow) - Channel 2 (outlet flow)" in the third channel, while activating the flow accumulation function;

Operation and maintenance personnel can view real-time flow, accumulated flow and difference data via the logger interface, and can also export data to a PC for analysis via RS485 or USB.

IV. Implementation Results: From "Data Blind Spot" to "Intelligent Monitoring"

The solution was delivered and deployed in March 2025 (contract signing date: 2025-03-18). After implementation, it brought multi-dimensional value to the customer:

Data Precision: The ±1% accuracy of the flow meter and the real-time calculation function of the logger control the flow difference monitoring error within 2%, fully meeting the needs of working condition judgment;

Operation and Maintenance Efficiency: Replacing the manual recording method, the operation and maintenance team can obtain data in real time, reducing fault response time by 80%;

Cost Controllability: The integrated equipment reduces hardware investment, and at the same time, problems such as pipeline blockages are detected early through flow difference monitoring, reducing engine maintenance costs;

Scenario Adaptability: Features such as the equipment’s pressure resistance and English interface perfectly match the cruise ship’s operating environment and the usage habits of the French team.

In this cooperation, China - Anhui JUJEA Manufacturer solved the power system monitoring pain points of the French cruise ship customer with a "customized hardware + scenario-based function" solution. The combination of its turbine flow meter and GT68R logger also provides a reusable reference solution for "flow difference monitoring" needs in fields such as shipping and chemical engineering.